Thermal insulation applied to equipment operating at high temperatures is a simple, high-impact technical solution: it reduces heat transfer to the environment, improves the process’s energy efficiency, and protects both people and equipment.

In this article, we cover these points and present real cases in which we applied the solution in industrial plants, resulting in fast payback for our clients.

What is “hot” thermal insulation?

Thermal insulation is a set of materials applied to equipment operating at elevated temperatures with the main purpose of reducing heat transfer to the external environment.

This allows thermal energy to remain concentrated where it is needed, lowers the energy consumption associated with the process, and protects structures and components from thermal variations that may cause damage over time.

Industries such as chemical, food and beverage, sugar-energy, pulp and paper, refineries, and other continuous thermal-operation processes often achieve strong financial and operational returns by implementing thermal insulation solutions.

Thermal insulation can be applied in different ways depending on the equipment’s needs. The fixed (conventional) model is the most common: it uses insulating material protected by a metal cladding, usually manufactured on site. It is recommended for continuous stretches that do not require frequent removal.

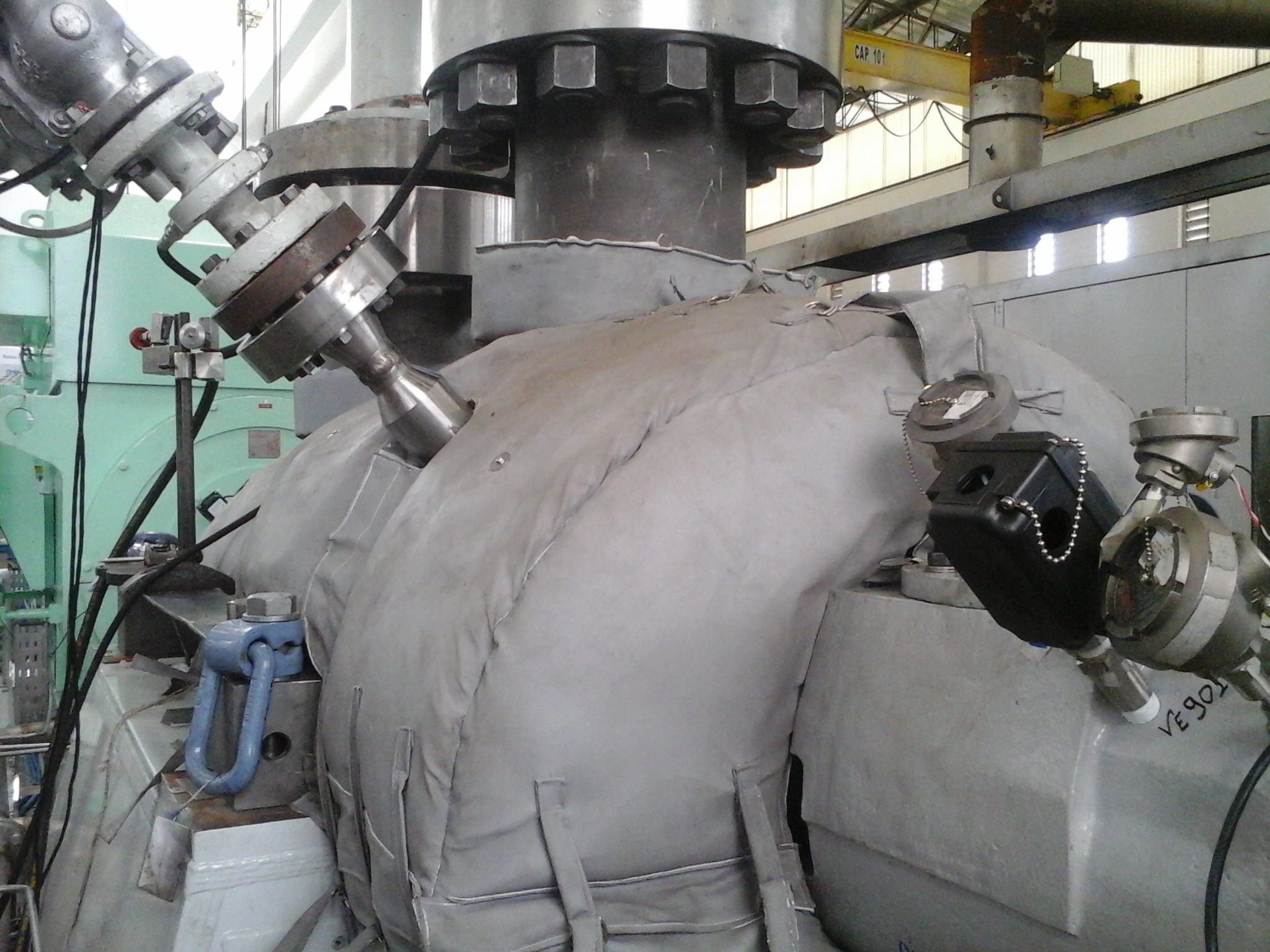

Removable insulation, however, is designed for quick installation and removal, making it ideal for valves, flanges, and points requiring frequent inspections. Manufactured to fit precisely using flexible fabrics and blankets, it does not affect the original structure. There is also a hybrid solution, combining fixed sections with removable insulation, balancing cost, efficiency, and practicality during maintenance.

How much can industrial thermal insulation save?

At Priner, we have extensive experience supporting the industry. Below, we present three cases where the application of removable insulation generated significant savings for companies.

Case 1: Insulation application in an automotive sector plant

In the automotive sector, a plant identified the need to reduce thermal losses and increase operational safety in one of its key productive assets: the aluminum melting furnace.

To meet this demand, a custom-designed removable thermal insulation system was implemented to optimize equipment efficiency and ensure greater reliability in the production process.

The project involved applying a ceramic fiber blanket with a density of 96 kg/m³ on equipment with a diameter of Ø 3,380 mm, operating at 270 °C on the hot face. After installation, the external surface (cold face) registered only 55.9 °C, significantly reducing energy loss.

Results showed expressive improvements:

- Heat loss without insulation: 5.416 kW/m²

- Heat loss with insulation: 0.261 kW/m²

- Thermal loss reduction: 95.2%

Financial and environmental impacts:

- Monthly savings: R$ 6,026.73

- Annual savings: R$ 72,320.78

- Investment value: R$ 220,912.54

- Payback time: ~36 months

- Carbon avoided: 3.45 tCO₂e/year

Case 2: Insulation application in a metallurgical plant

A metallurgical plant identified the need to improve energy efficiency in one of its large-diameter pipelines operating at extremely high temperatures.

The goal was to reduce thermal loss, increase operational safety, and improve process reliability. A custom-designed removable insulation system was installed to withstand the severe operating conditions.

The project involved applying ceramic fiber blanket with a density of 96 kg/m³ on a 1,820 mm diameter pipeline operating at 500 °C. After installation, the cold-face temperature dropped to just 55.3 °C, improving workplace safety and energy efficiency.

Results were also significant:

- Heat loss without insulation: 20.654 kW/m²

- Heat loss with insulation: 0.256 kW/m²

- Thermal loss reduction: 98.8%

Financial and environmental impacts:

- Monthly savings: R$ 211,984.06

- Annual savings: R$ 2,543,808.71

- Investment value: R$ 119,271.05

- Payback time: ~1 month

- Carbon avoided: 121.42 tCO₂e/year

Case 3: Insulation application in a food industry plant

A food industry plant needed to reduce thermal losses and improve operational reliability in one of its process furnaces. The goal was to optimize energy use, improve operator safety, and support production continuity.

A custom-engineered removable insulation system was designed and installed, based on the asset’s dimensions and structural interferences identified on site.

The project involved applying ceramic fiber blanket with a density of 96 kg/m³ on equipment with a diameter of 1,830 mm, operating at 300 °C. After installation, the cold-face temperature dropped to 53 °C, reducing accident risks and improving energy efficiency.

Results achieved:

- Heat loss without insulation: 6.697 kW/m²

- Heat loss with insulation: 0.228 kW/m²

- Thermal loss reduction: 96.6%

Financial and environmental impacts:

- Monthly savings: R$ 30,253.28

- Annual savings: R$ 363,039.32

- Investment value: R$ 220,912.54

- Payback time: ~2 months

- Carbon avoided: 17.33 tCO₂e/year

Why consider this solution?

In addition to financial savings, thermal insulation — as demonstrated by the cases — provides several other benefits for industrial environments:

- Energy efficiency and sustainability: less heat lost means less energy needed for generation or recovery.

- Operational safety: cooler external surfaces reduce the risk of burns and accidents.

- Asset preservation: lower thermal radiation on nearby equipment and instruments increases their service life.

- Maintenance practicality: removable systems allow quick interventions without damaging the insulation.

If your industry is also looking to reduce thermal losses and improve energy efficiency, our team is ready to support you with tailor-made solutions.

Explore all our thermal insulation solutions here.