Failure analysis stands as one of the most vital tools in contemporary engineering, enabling not only the understanding of failures in components and equipment but also the prevention of similar incidents in the future. This systematic investigative approach has become increasingly critical in a world where operational reliability and safety are paramount.

When an industrial component fails, multiple factors may be involved, ranging from mechanical overloads and pre-existing defects to design errors and degradation caused by the operating environment. Failure analysis identifies the root cause of these issues through a combination of various analytical and investigative techniques.

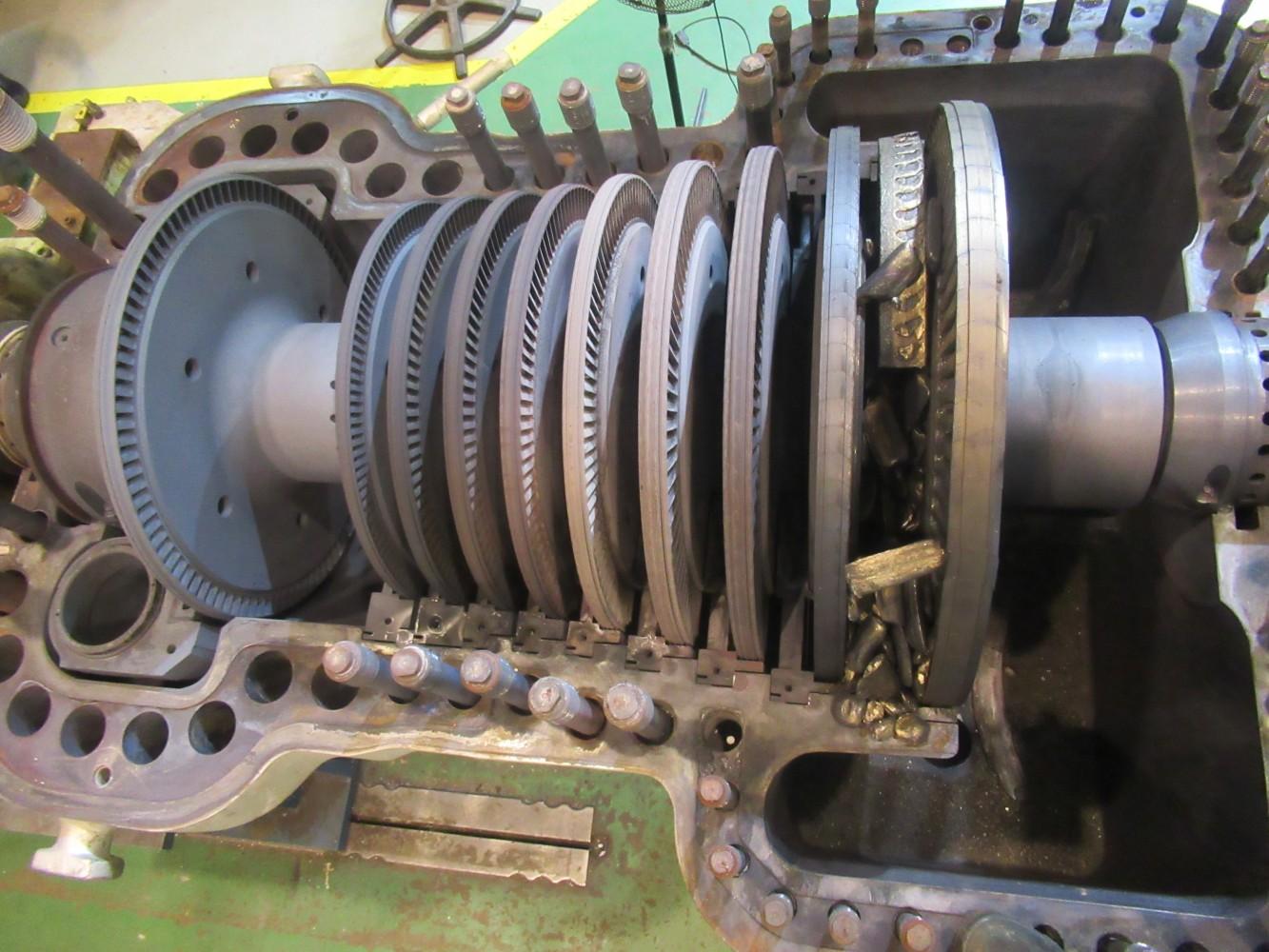

The process involves a detailed metallurgical evaluation, including chemical and metallographic analyses that reveal the material’s composition and internal structure. Microscopy, both optical and electron, plays a pivotal role in this phase, allowing the visualization of microstructural features indicative of the conditions that led to the failure.

The use of Scanning Electron Microscopy (SEM) combined with Energy-Dispersive Spectroscopy (EDS) enables detailed examination of fracture surfaces and chemical analysis of specific microscopic regions. Meanwhile, mechanical tests complement the investigation with quantitative data on material properties. Tensile, impact, hardness, and more complex fracture mechanics analyses provide essential insights into whether the material met specifications and how it performed under critical conditions that led to failure.

Numerous industrial sectors rely on failure analysis to maintain and enhance their operations. In the sugar and energy industry, for instance, it aids in understanding issues with processing equipment. In the automotive sector, it contributes to developing safer components. In mining and steel industries, it helps prevent failures in high-cost critical equipment.

Modern chemical analysis techniques for failure investigation are diverse and complementary. Optical emission spectrometry allows precise analysis of the composition of steels and metal alloys, including the critical determination of carbon content. X-ray fluorescence (XRF) provides a non-destructive and versatile analysis, particularly useful for field applications through Positive Material Identification (PMI).

A particularly significant aspect is the analysis of corrosion products and scale buildup. In industrial environments, the formation of oxides and deposits can severely impair component performance and lifespan. Chemical analysis of these deposits enables the identification of their origin and the development of effective preventive strategies.

The future of failure analysis points toward greater integration with digital technologies and advanced data analysis techniques. Combining traditional investigative methods with cutting-edge technologies allows for a deeper and more accurate understanding of failure mechanisms.

Our Experience at Priner

At Priner, we have a specialized team and state-of-the-art laboratories equipped to conduct thorough and precise failure analyses on industrial components. Our engineers bring extensive experience in investigating failures across diverse sectors, including sugar and energy, power generation (wind/steam), agriculture, metalworking, mining, fertilizers, and food industries.

Our multidisciplinary approach integrates metallurgical, chemical, and mechanical analyses, delivering a comprehensive diagnosis of failure causes and precise recommendations for preventing future occurrences.