Sugarcane mill shafts are considered strategic components within the milling system. Their failure can lead to significant losses due to both the high replacement cost and the downtime required for replacement. Additionally, extraction losses may occur as a result of bypassing the affected mill set.

Photo 1 – Sugarcane mill shaft fractured by fatigue during harvest season.

However, failure analyses of fractured shafts conducted at Priner’s laboratory show that such failures rarely result from components simply reaching their expected service life. Instead, these failures are almost always linked to adverse conditions imposed on the shafts due to poor maintenance or material defects.

Very few shafts manufactured from suitable materials have failed without first undergoing welding repairs, suffering from severe corrosion in critical areas such as the sealing region (which promotes crack nucleation), or entering the harvest season already compromised by cracks due to the lack of preventive inspection or poorly executed weld repairs.

Photo 2 – The fracture surface of nearly all broken shafts shows crack propagation caused by fatigue and indicates the shaft was oversized; in other words, the area affected by fatigue crack propagation is significantly larger than that of the final catastrophic fracture.

We confidently state that, when proper preventive and corrective maintenance is carried out and there are no extreme operational adversities, the service life of sugarcane mill shafts tends to be long. This is because these components are overengineered, and their fatigue limits far exceed the stresses encountered under normal operating conditions.

However, deep notches, rough surfaces resulting from corrosion, cracks, and sharp corners act as stress concentrators. When combined with misalignment of components, these features significantly reduce the fatigue life of the shaft.

As the term suggests, stress concentrators cause a localized increase in stress. These increases can often exceed — sometimes greatly — the material’s stress tolerance, resulting in crack nucleation. Once formed, cracks can propagate under normal operating conditions, eventually leading to shaft failure during the harvest or requiring the shaft to be scrapped or reconditioned through welding during the off-season.

Photo 3 – Shaft without the wear sleeve, showing severe corrosion and crack nucleation in the sealing region.

Parameters to Avoid Sugarcane Mill Shaft Failure

We maintain that if certain technical parameters are followed, shaft fractures under normal operating conditions are highly unlikely. These parameters can be summarized as follows:

Procure raw materials that meet technical specifications. To support this, we offer free access to ETP 100-01 “Forged Carbon Steel Shaft for Mills,” which can be used as a reference during procurement.

Photo 4 – Microstructures of SAE 1045 steel with and without heat treatment. (A): As-forged steel (coarse and brittle). (B): Same steel with proper heat treatment—more tough and ductile, offering significantly better resistance to crack propagation.

Manufacture shafts according to sound design practices, especially considering fracture mechanics. This includes smooth transition regions, the absence of sharp corners, and high-quality machining with low surface roughness.

Ensure the sealing system of the shaft sleeves is well-maintained to minimize the occurrence of scratches and corrosion in that region. Doing so helps to avoid the need for weld-based repairs.

Avoid assembling rollers with excessive clearance, and perform proper fitting of keys. This prevents cracks in the keyway channels.

At the end of the harvest, conduct preventive inspections using visual and dimensional analysis and non-destructive testing (NDT), including magnetic particle testing, ultrasonic testing, and liquid penetrant testing—always performed by qualified personnel.

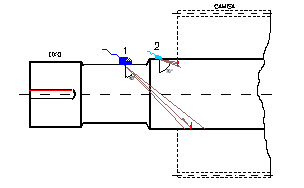

Special care must be taken with shafts that will not have their sleeves removed (reground). In such cases, ultrasonic inspection with an angle-beam transducer is required to detect cracks in the regions underneath the sleeve. This test is critical and must be carried out by qualified personnel.

Figure 1 – Typical representation of ultrasonic probe positioning for crack detection in a shaft with the sleeve mounted.

Cracks identified during preventive inspections must be removed through machining or localized grinding (or gouging, if needed). The resulting cavities must then be inspected using fluorescent magnetic particle testing to confirm complete crack removal.

Cavities or regions requiring welding must be recovered using an appropriate procedure, which should always include the following parameters:

- Qualified welding procedure and certified welders.

- Filler materials from reputable manufacturers, handled according to relevant standards.

- Pre-heating and post-weld heat treatment (PWHT) for stress relief, performed with resistive heating systems and proper thermal insulation.

- Monitoring of all specified welding parameters during the repair process.

- Post-machining inspection using fluorescent magnetic particle testing and ultrasonic testing, along with visual and dimensional checks of the repaired areas.

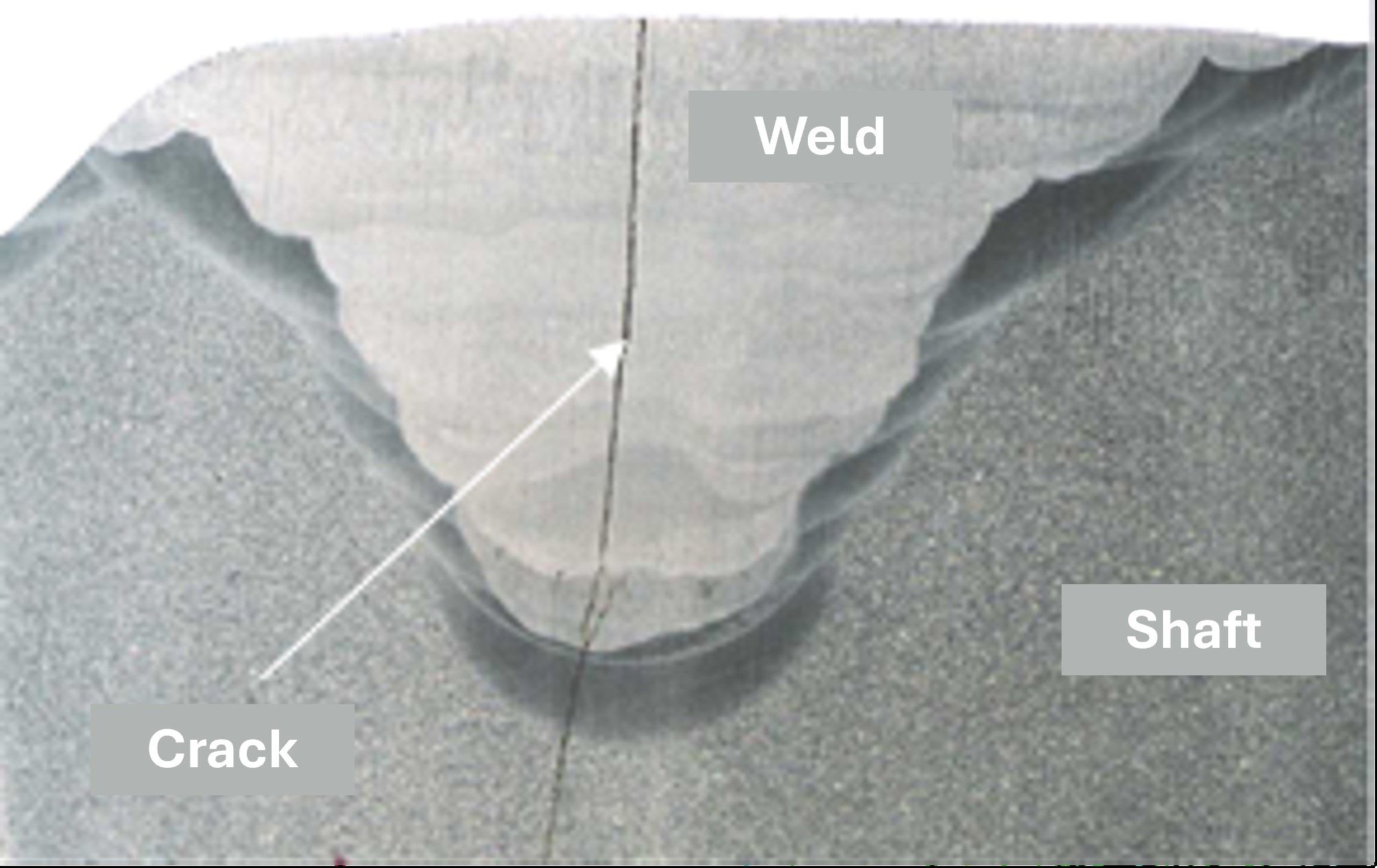

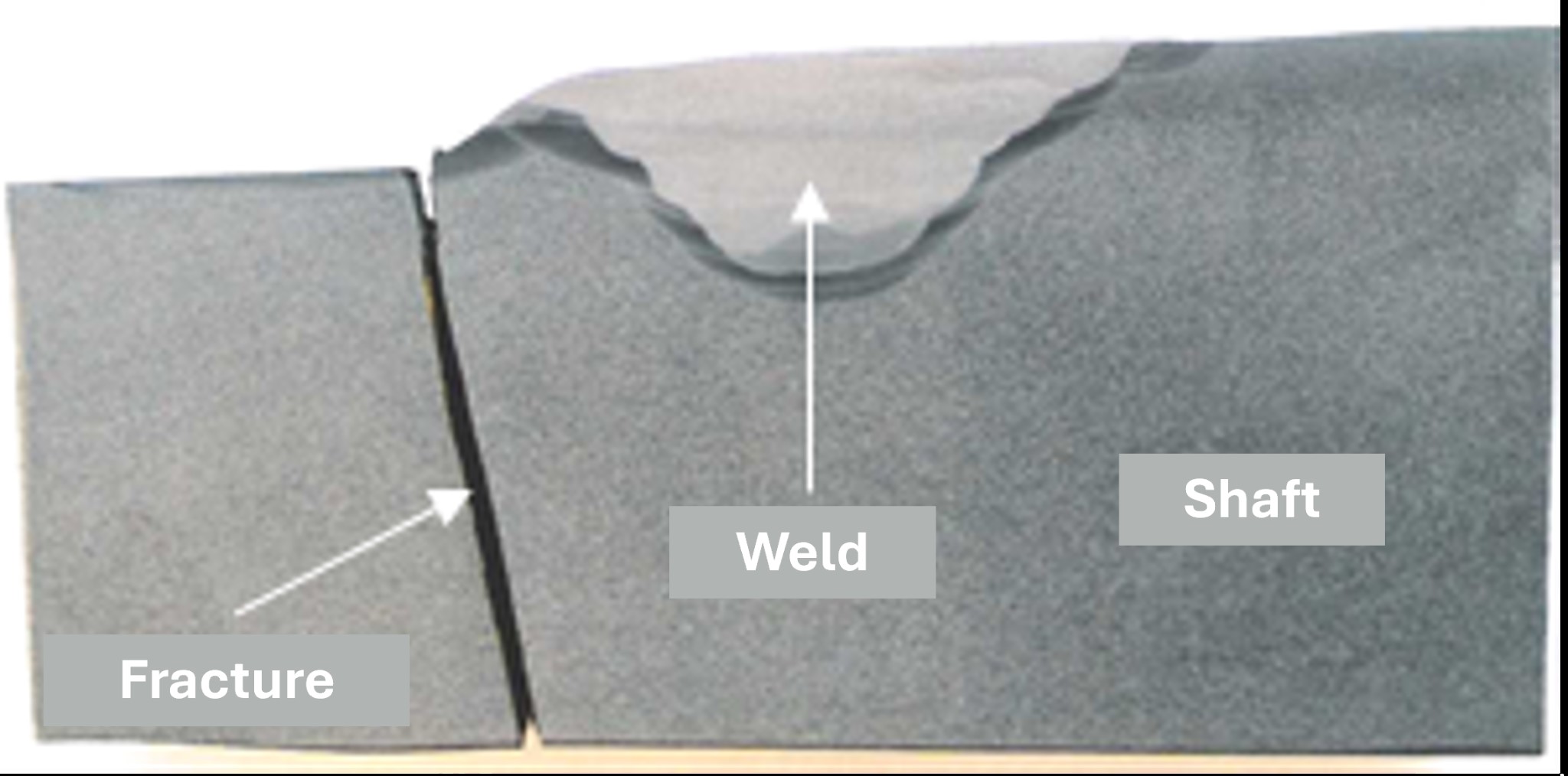

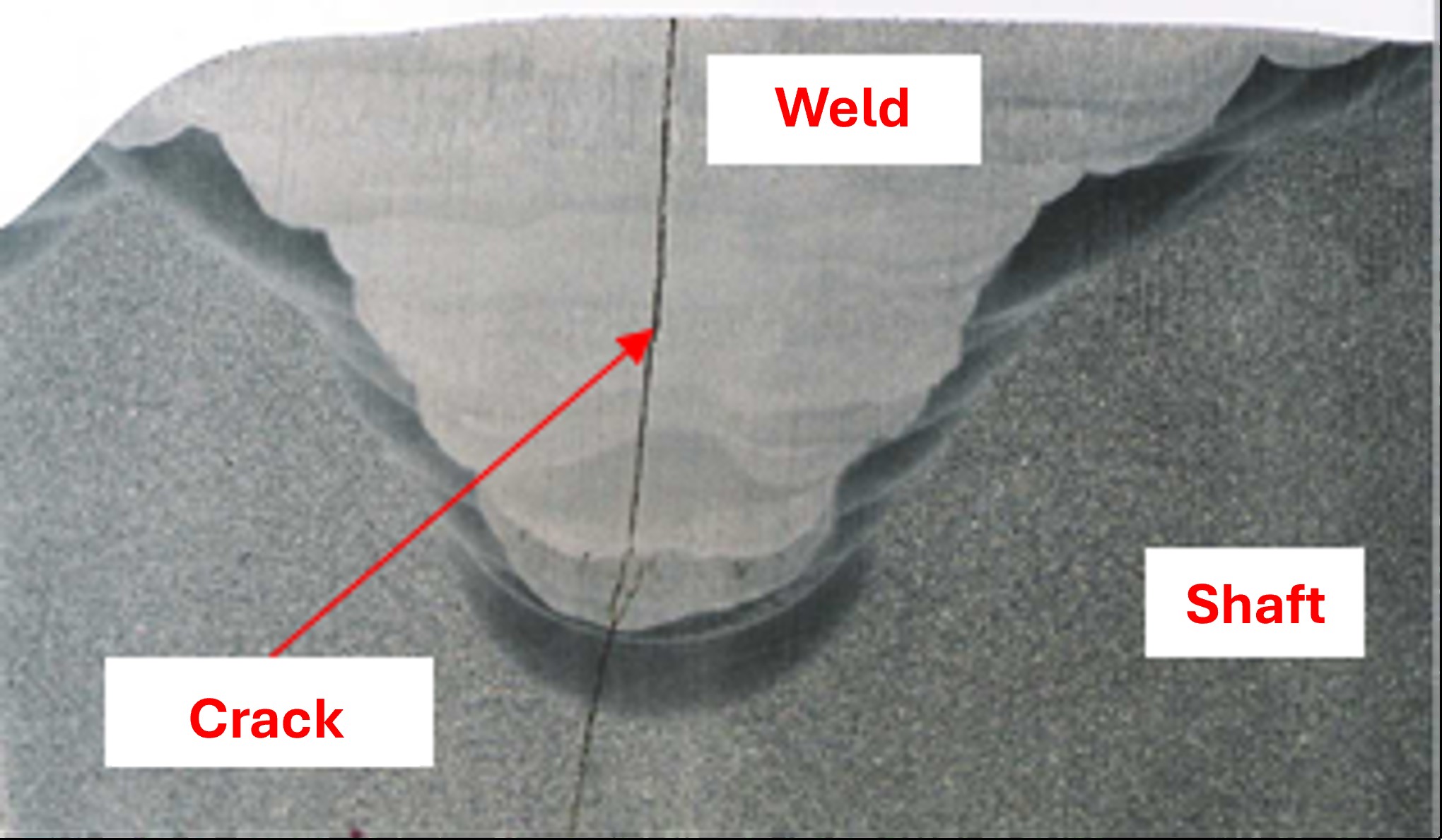

Photo 5 – Cross-section of a shaft inadequately repaired by welding, showing crack initiation in the weld and, elsewhere, fracture initiated in the HAZ (Heat-Affected Zone).

Cross-section of a shaft improperly repaired by welding, showing crack initiation in the weld zone.

This article specifically addresses the technical aspects of sugarcane mill shafts, but similar large components made from the same material are also used in sugar and ethanol plants—such as in press roller shafts, feeder table shafts, and exhaust fan shafts. Therefore, the recommendations provided here should be extended to all of these components.

Priner: Extensive Experience in the Sugar-Energy Sector

With our unit located in Sertãozinho, we provide essential inspections and metallurgical evaluations that contribute to operational continuity and performance in the sugar-energy sector.

Equipped with cutting-edge technology and quality certifications, our team has a proven track record in the industry, always enabling safe and efficient operations.