Abstract

This article presents the general design, analysis, and execution guidelines used in the sizing, stability assessments, loading conditions, and calculation methods for the structural reinforcement of the main dam of the Risoleta Neves Hydroelectric Power Plant (UHE), located between the municipalities of Rio Doce and Santa Cruz do Escalvado, Minas Gerais (MG), Brazil. It describes the conditions for the proper execution of the detailed design, ensuring the performance and durability of the structures while prioritizing safety, reliability, and cost-effectiveness.

The main dam comprises the left and right bank dams, spillway, and water intake, constructed with Roller-Compacted Concrete (RCC) and divided into 21 blocks separated by contraction joints. The construction methodology involved the use of plain concrete blocks to reinforce the existing structure. pt.wikipedia.org

1. Introduction

In 2010, Federal Law No. 12.334 established the National Dam Safety Policy (PNSB) to enhance dam safety and oversight. The PNSB aims to ensure safety standards for dams used for water storage, final or temporary disposal of tailings, and accumulation of industrial waste (BRASIL, 2010). The policy was enacted to standardize safety measures, reduce accident risks, enhance safety in surrounding areas, and promote dam safety awareness. pt.wikipedia.org

Despite the numerous benefits of dam construction, potential structural failures raise significant concerns due to the severity of accidents involving such structures. Coexisting with these risks is unacceptable (Oliveira, 2012).

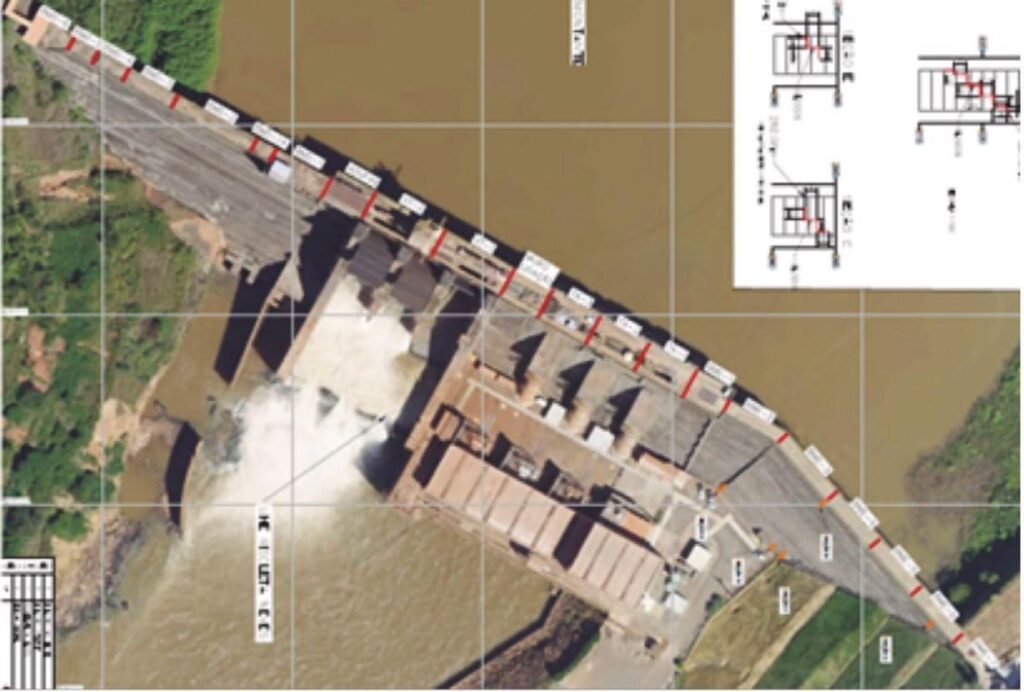

The main dam at UHE Risoleta Neves consists of left and right bank dams, a spillway, and a water intake, all built with Roller-Compacted Concrete (RCC) and contraction joints between blocks, as shown in Figure 1. The power generation circuit includes three water intake blocks, penstocks, and a powerhouse designed with Conventional Vibrated Concrete (CVC).

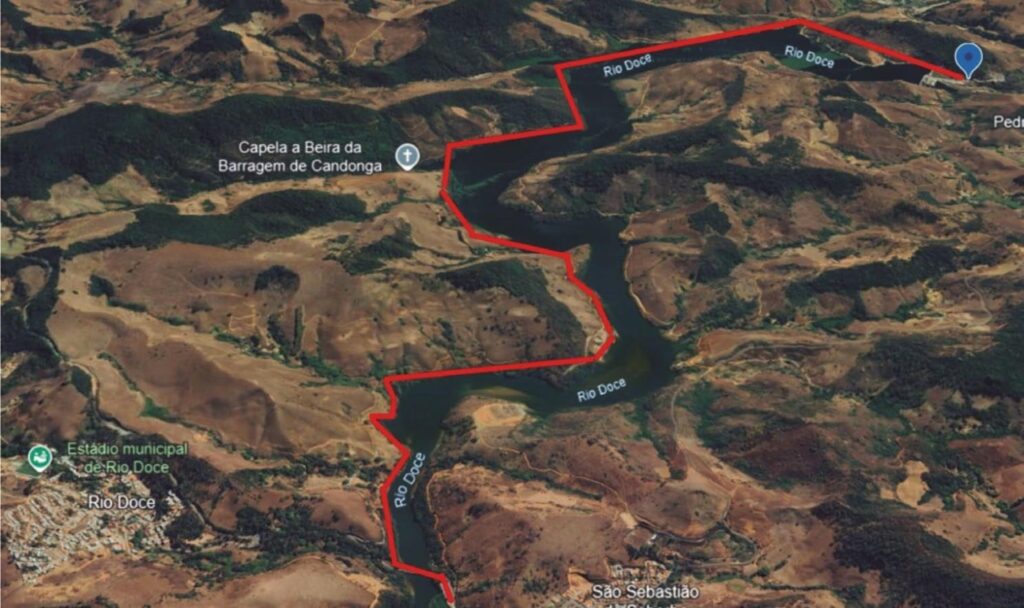

The UHE Risoleta Neves is located approximately 15 km from the municipality of Rio Doce. Access to the site is via unpaved roads on the left bank, with access to the right bank provided through the dam itself, as there is no vehicle crossing over the Rio Doce in the dam’s vicinity. Access to the UHE is indicated in Figure 2 in red.

Figure 1 – Dam, penstocks, and powerhouse (source: Gmaia digital archive)

The reinforcement activities for the UHE Risoleta Neves dam involved placing concrete on the downstream face of the dam, adhering to best engineering practices, including surface preparation, anchorage between new and existing concrete, temperature control of the new concrete, use of climbing formwork, curing, and other intrinsic factors of the execution process. Stability assessments revealed that blocks BME-01, BME-02, BME-03, BME-04, BME-05, BMD-01, BMD-03, BMD-04, BMD-05, BMD-06, and the connecting wall did not meet the adopted safety criteria, necessitating reinforcement. vale.com

Figure 2 – Main access routes to UHE Risoleta Neves

2. Problem Description

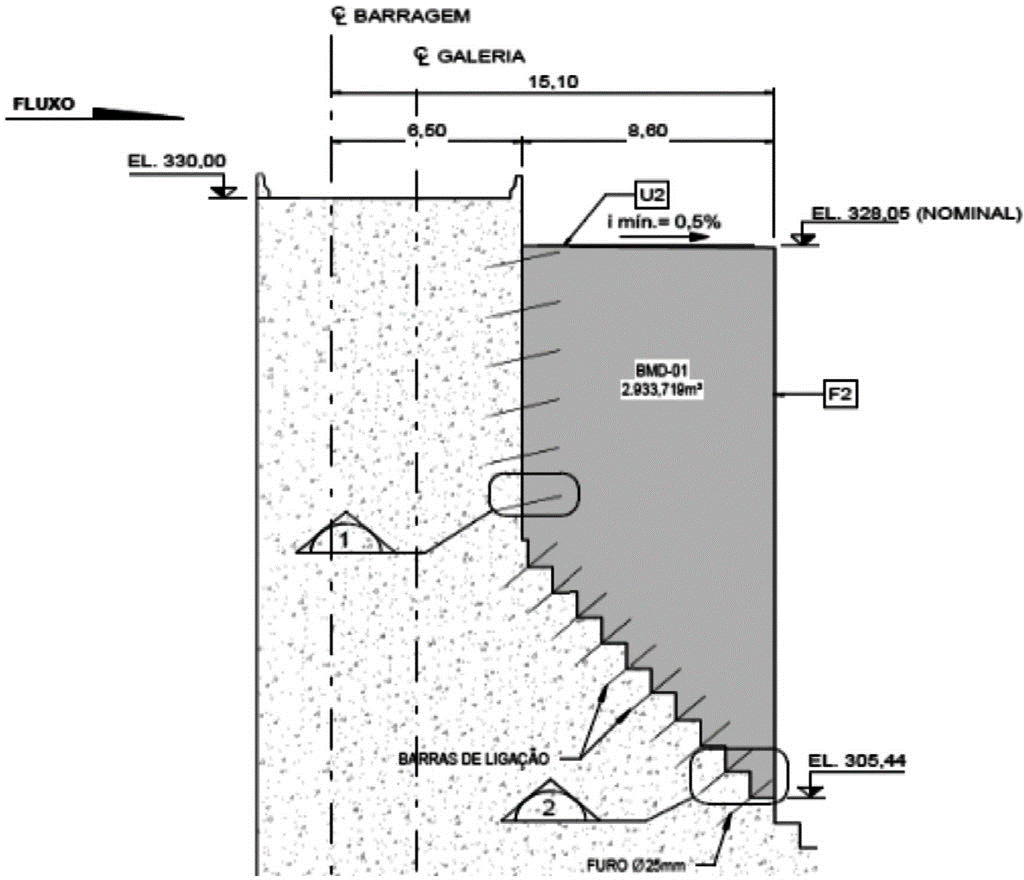

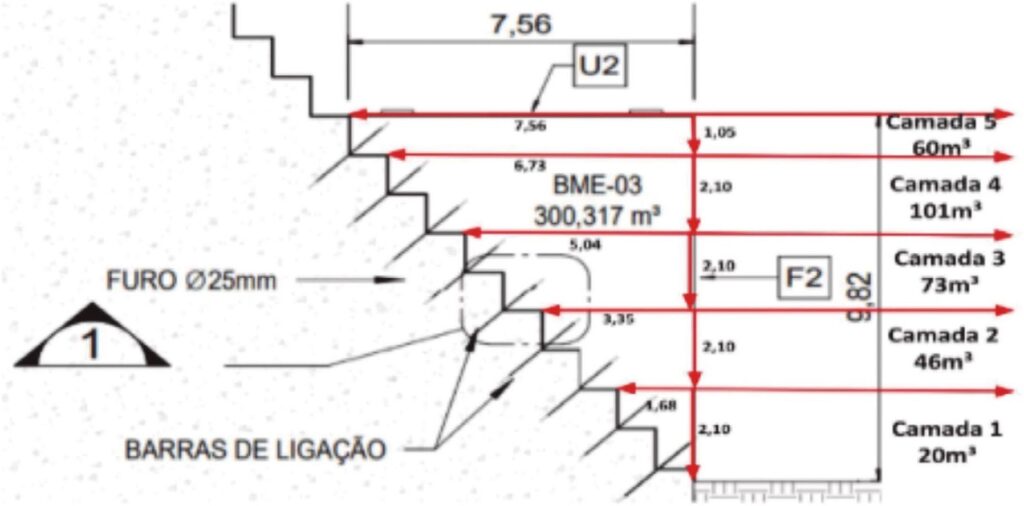

The dam is a concrete structure with a crest at elevation 330.00 m, featuring a spillway with an ogee crest at elevation 311.00 m and a water intake with a sill at elevation 308.20 m. Reinforcement activities involved applying Conventional Vibrated Concrete (CVC) and/or pumpable concrete over the RCC on the downstream “neck” of 11 dam structures: BME-01, BME-02, BME-03, BME-04, BME-05, BMD-01, BMD-03, BMD-04, BMD-05, BMD-06, and the connecting wall, as specified in the detailed design (Figure 3).

The reinforcement was necessary to meet safety and stability criteria following the 2015 Fundão Dam collapse, which deposited approximately 9.6 million cubic meters of tailings in the UHE Risoleta Neves reservoir, halting operations. oeco.org.br

Figure 3 – Cross-section of reinforcement for BMD-01

2.1 Analysis Phase

The analysis began with a review of the original design documents from 2002 to 2004, alongside mechanical surveys, videoscopy, tests, and evaluation reports conducted post-Fundão Dam collapse in 2021. The objective was to understand the geological model of the area and refine the geomechanical parameters used in prior design stages. These efforts supported the stability analysis of the concrete structures under new operational conditions with reinforcements, based on the safety factors defined by Eletrobras’ Hydroelectric Power Plant Design Criteria.

The UHE Risoleta Neves is situated within the Mantiqueira Complex, characterized by orthogneisses, amphibolites, migmatites, and meta-ultramafic rocks.

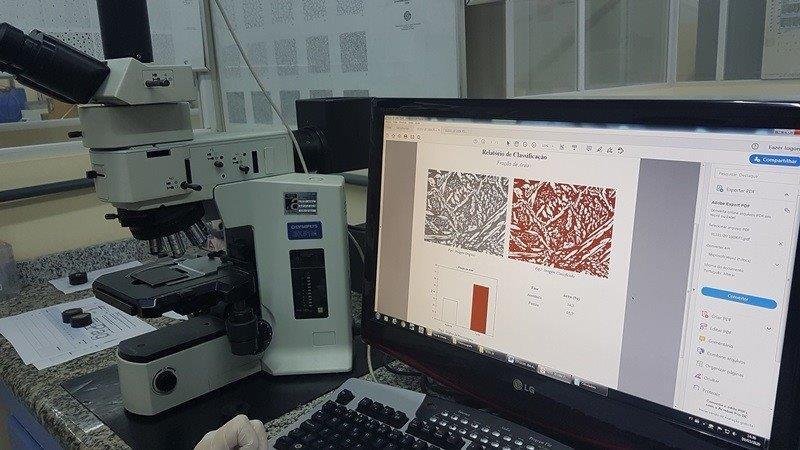

Figure 4 – UHE Risoleta Neves before the Fundão Dam collapse

3. Executed Services

Initial activities involved experimental high-pressure water jetting tests to demonstrate the method’s effectiveness in cleaning the downstream face of the dam where reinforcements would be applied.

Figure 5 – High-pressure water jetting test

Subsequently, the first layer of block BME-02 was cleaned using high-pressure water jetting, followed by drilling for the installation of connecting bars.

Figure 6 – Drilling for connecting bars

After completing the drilling and cleaning of the holes, the installation of connecting bars began.

Figure 7- Anchorage of connecting bars

With high-pressure water jetting, connecting bar installation, and climbing formwork assembly completed, the contractor Gmaia proceeded with the installation of connecting bars and formwork assembly for blocks BME-03 and BME-04.

Figure 8 – High-pressure water jetting of BME-04

The first concrete pour, authorized by the client, was performed on blocks BME-02 and BME-03. The surface to be concreted was treated with high-pressure water cutting to remove dirt, fungi, dust, and loose particles, ensuring good adhesion. Polyurethane injections were applied at points with visible seepage in the original dam structure.

Figure 9 – Concrete pouring of the first layer of block BME-02

3.1 Formwork Assembly

The formwork and anchoring systems were designed to withstand the pressure from concrete pouring and vibration, securely fixed in the correct position and sufficiently sealed to prevent mortar loss.

Figure 10 – Climbing formwork system

Figure 11- Internal tie-rod system (formwork)

4. Technologies Used

4.1 Concrete Technology Considerations

To meet the project’s schedule expectations, a strategic mix of Conventional Vibrated Concrete (CVC) and pumpable concrete was used. The mix was designed with slump and workability characteristics compatible with the required production cycle—mix release at the concrete plant, transportation, pouring, compaction, and curing.

4.2 Thermal Study and Concrete Temperature Monitoring

The concreting plan adhered to a maximum temperature limit of 65°C in any region of the concrete mass to mitigate delayed ettringite formation.

4.3 BIM for Planning and Data Storage

Building Information Modeling (BIM) software facilitated improved client interaction, enhancing project modeling and planning. During the planning phase, BIM enabled visualization of the entire project execution. It also allowed tracking of completed work and storage of relevant data, such as concrete temperature, compressive strength from test specimens, and pour dates, ensuring future traceability.

A 3D project model was created using Autodesk’s REVIT software, providing an initial view of the dam structure.

Figure 12 – Sketch of the initial concreting layer plan

Figure 13 – BIM modeling

4.4 Topographic System with Point Clouds

Concreting progress was monitored using the Hovermap Laser Scanner, which collects up to 600,000 points per second with millimeter precision. Based on SLAM (Simultaneous Localization and Mapping), this system enables continuous scanning in motion.

Figure 14 – Point cloud

4.5 Climbing Formwork System

The climbing formwork system was used, where the formwork is reused in subsequent concreting stages, supported by anchorages from the previously poured layer. This system is ideal for special industrial structures, bridge piers, viaducts, and most hydroelectric power plant structures.

Figure 15 – Block with climbing formwork system

5. Conclusions

Stability analyses to meet the required safety factors resulted in increased cross-sectional areas for each block, requiring an additional 21,000 m³ of concrete with a minimum specific weight of 2.3 t/m³.

At the peak of activities, the workforce reached 350 employees. A detailed action plan with a well-defined execution methodology was established in collaboration with the client, ensuring micro-planning for each project stage.

The reinforcement of the UHE Risoleta Neves dam, completed in December 2022, enabled the reservoir’s refilling and the resumption of operations in March 2023, restoring energy generation capacity and addressing the socioeconomic impacts on Rio Doce and Santa Cruz do Escalvado. samarco.comoeco.org.br

6. Keywords

Dam, dam reinforcement, hydroelectric power plant, UHE

7. References

[1] ANM. Agência Nacional de Mineração. Classificação de Barragens de Mineração. Available at: https://app.anm.gov.br/SIGBM/Publico/Estatistica.

[2] ANM. Agência Nacional de Mineração. Relatório anual de segurança de barragens de mineração 2019. 2020.

[3] ANM. Agência Nacional de Mineração. Segurança de barragens focada nas barragens construídas ou alteadas pelo método a montante, além de outras especificidades referentes. Available at: https://www.gov.br/anm/pt-br/assuntos/noticias/2019/notaexplicativa-sobre-tema-de-seguranca-de-barragens-focado-nas-barragens-construidas-ou-alteadas-pelo-metodo-a-montante-alem-de-outras-especificidades-referentes.

[4] BRASIL. Lei Nº 12.334, de 20 de setembro de 2010. Estabelece a Política Nacional de Segurança de Barragens destinadas à acumulação de água para quaisquer usos, à disposição final ou temporária de rejeitos e à acumulação de resíduos industriais, […]. Brasília, DF: Presidência da República, [2020].

[5] COSTA, G. B. R.; LAU, G. R.; SILVA, C. F.; MANTEL, M. B. C.; PERES, M. M. C.; LUNA, T. N. S. S.; SILVA, P. N. Rompimento da barragem em Brumadinho: um relato de experiência sobre os debates no processo de desastres. SAÚDE DEBATE, v. 44, n. especial 2, p.377-387, 2020.

Authors

Leandro Filgueiras

Technical Manager. With 15 years of experience as a structural engineer and technical manager in geotechnical works, retaining structures, excavations, structural designs, structural reinforcements, industrial shutdown works, dam reinforcements, and geotechnical reinforcements with resin injections.

Heraldo Xavier

Operational Manager. Responsible for Gmaia’s operational management since 2018, overseeing production teams, planning, and contract administration. Extensive experience in underground and infrastructure works and complex maintenance projects across industrial and public sectors.

Bruno Barbosa

Budget Assistant. At Gmaia, handles budgeting and technical activities related to projects. Experienced in budgeting, planning, and procurement in energy and heavy civil construction sectors.

Marcelo Miranda Botelho

Engineer. Civil Engineering graduate from the Federal University of Minas Gerais (UFMG/1999). Specializes in concrete, dams, and rehabilitation.

Rafael Holanda

Engineer. Specialist in concrete, soil (geotechnics), and pavement quality control, with detailed test analysis and complex reporting, including compliance with project and regulatory parameters, and proposing solutions and strategies for infrastructure projects, including airports, ports, highways, stadiums, dams, hydroelectric plants, tunnels, and wind farms.