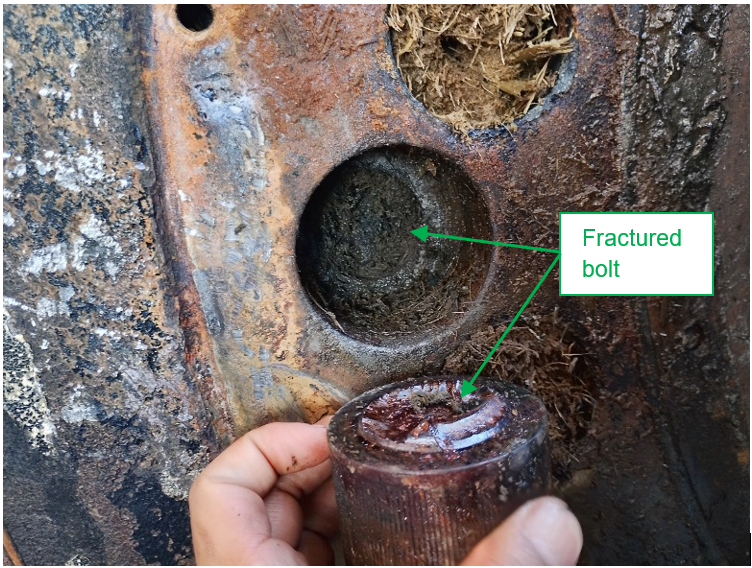

In the sugar-energy sector, unplanned shutdowns of mills, boilers, and large equipment can lead to significant losses. Among the silent and recurring causes are industrial bolts, simple components, yet essential for safety and operational continuity.

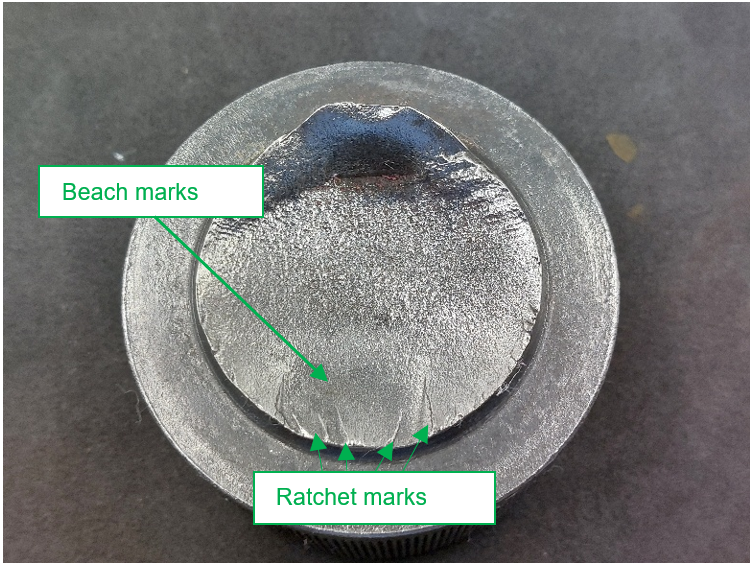

At Priner’s laboratories, bolt fractures caused by fatigue, improper torque, or the use of out-of-spec materials are common findings. Even when the torque wrench shows an apparently correct value, factors such as excessive friction, thread imperfections, or misalignments can compromise the actual tension applied, promoting the development of cracks that eventually lead to failure.

Another frequent scenario involves bolts with lower strength than required by the design, resulting in deformations and premature failures. This may stem from technical specification errors, procurement issues, lack of traceability, or inadequate quality control.

By combining materials engineering with advanced laboratory infrastructure, Priner conducts thorough investigations through mechanical, metallographic, and chemical testing. We assess mechanical properties, metallurgical structure, and material composition to identify root causes of failures and prevent recurrence.

We also apply the Fitness-for-Service (FFS) methodology, based on international standards API 579 and BS 7910, to assess the integrity of damaged components in operation and support decisions regarding continued use, repair, or replacement.

In industrial environments with high loads and pressures, there is no room for preventable failures. Investing in inspection, testing, and prevention is a strategic decision and Priner is ready to support your plant on the journey toward greater safety, performance, and reliability.