Determining the joint efficiency coefficient of welded joints is a critical aspect of ensuring the quality and safety of products across various industries. In this article, we will discuss the importance of removing weld reinforcement during this process and how phased array ultrasonic testing plays a crucial role in this step.

As specified in ASME Section V, Article 4, item T-471-5, it is essential that the weld does not interfere with the inspection. To meet this requirement, the weld reinforcement must be carefully ground down. But why is this so important? Removing the reinforcement allows ultrasonic probes to move unobstructed along the intersections of vertical and circumferential welds in tanks, ensuring a precise and comprehensive inspection.

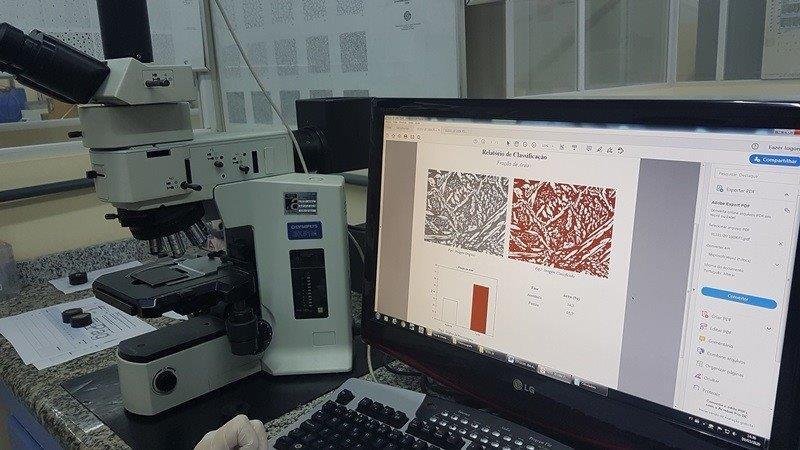

Phased array ultrasonic testing plays a pivotal role in this context. This advanced technique enables the identification of potential discontinuities, such as cracks, porosity, or inclusions, that could compromise the integrity of welded joints. However, to obtain reliable results, it is critical to remove the weld reinforcement, allowing ultrasonic probes to scan the entire length of the welded joint and accurately detect these discontinuities. This enables appropriate corrective measures to be taken, ensuring the quality and safety of the final products.

At our company, we have a specialized team skilled in non-destructive testing, including phased array ultrasonic testing. We are committed to providing efficient and reliable solutions to meet our clients’ inspection and quality needs.

If you are seeking welded joint inspection services or would like to learn more about phased array ultrasonic testing, please don’t hesitate to contact us. We’ll be happy to assist you and provide the information needed to enhance the efficiency and reliability of your welds.