Non-Destructive Testing (NDT) is a fundamental tool for evaluating the integrity of materials and structures. In this article, we will explore what NDT entails, its main techniques, benefits, and applications across various industries. If you want to understand the importance of NDT and how it ensures safety and quality in multiple sectors, keep reading!

What is Non-Destructive Testing (NDT)?

Non-Destructive Testing (NDT) refers to methods used to assess the properties and integrity of materials without causing damage. These tests are essential in industries such as petrochemical, civil construction, manufacturing, and more, as they allow the detection of flaws and irregularities that could compromise the safety and functionality of structures and components.

The core principle of NDT is to perform measurements and tests without causing permanent changes to the tested materials. This means that after testing, the material remains suitable for use, a significant advantage over destructive testing, which often renders the tested object unusable.

There are various NDT techniques, each with its own specifics, advantages, and limitations. The most common include:

- Ultrasonic Testing: Uses high-frequency sound waves to detect internal flaws. It is highly effective for measuring thickness and identifying discontinuities.

- Radiography: Employs ionizing radiation to create internal images of materials, enabling the identification of flaws, welds, and other features.

- Magnetic Particle Testing: Used on ferromagnetic materials, this technique involves applying a magnetic field and fine particles to detect surface and near-surface discontinuities.

- Eddy Current Testing: Utilizes an electromagnetic field to identify changes in material conductivity, useful for detecting flaws in conductive materials and metals.

These techniques are critical for maintaining the safety and reliability of systems, equipment, and structures. By using NDT methods, companies can ensure their products meet quality and safety standards, preventing accidents and failures.

The importance of NDT is evident in the reliance of many industries on the reliability of their components. For example, in the aerospace industry, passenger safety depends directly on the integrity of aircraft components. Similarly, in the automotive sector, structural failures can lead to severe accidents.

Moreover, NDT optimizes maintenance processes. Regular inspections allow the identification of critical areas requiring attention before they become major issues, reducing repair costs and extending asset lifespan.

One of the main challenges in implementing NDT is selecting the most appropriate technique for each situation. Factors such as material type, the type of flaw to be detected, and environmental conditions must be considered. Each technique has its limitations, and sometimes a combination of methods is necessary to achieve the best results.

NDT also offers fast and efficient results. Most techniques can be performed on-site, avoiding the need to remove components, which saves time and resources. This is particularly beneficial in high-production environments where minimizing downtime is critical.

Another key feature of NDT is the ability to repeat tests. Since no damage is caused to the material, multiple tests can be conducted over a component’s lifespan, enabling continuous monitoring of integrity and preventing critical failures.

NDT is also widely used in research and development projects. By testing new alloys, composites, and innovative technologies, industries can validate product efficacy and durability before market release.

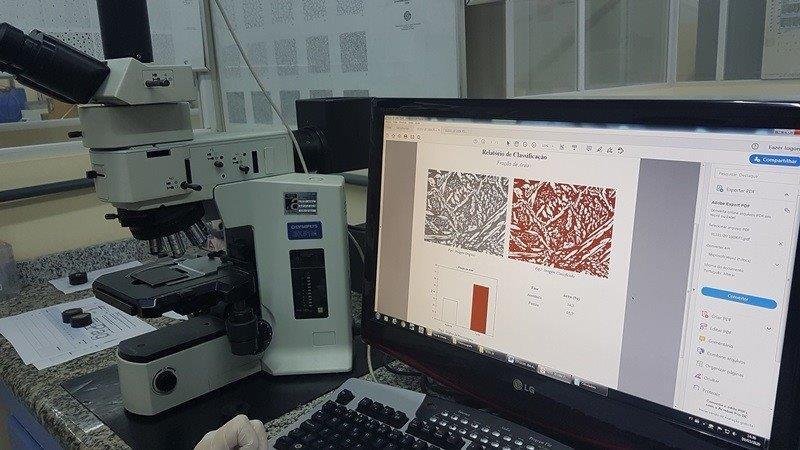

Recent technological advancements have brought innovations to NDT. The integration of artificial intelligence and machine learning, for instance, is starting to enhance data analysis, enabling the identification of patterns that might be missed in traditional manual analyses.

The training of qualified professionals for NDT is crucial. Certifications and specialized training are necessary to ensure operators understand the techniques, accurately interpret results, and adhere to safety standards. An inadequately trained technician could produce erroneous data or, in extreme cases, put lives at risk.

With the growing demand for safety and quality across all sectors, the importance of NDT is only increasing. Companies that adopt these methods not only improve product quality but also enhance consumer trust and market positioning.

In conclusion, NDT is a vital tool for maintaining material and structural integrity, representing a strategic investment to ensure trust and safety across various industries. Proper technique selection, regular inspections, and qualified professionals are key to successful NDT implementation.

Main Non-Destructive Testing Techniques

Non-Destructive Testing (NDT) is essential for evaluating material and structural integrity in industries such as construction, aerospace, and petrochemical. Each technique has unique characteristics, enabling the identification of flaws and irregularities that could compromise component safety and functionality. This section covers the main NDT techniques, their applications, and advantages.

- Ultrasonic Testing

Ultrasonic testing uses high-frequency sound waves to measure and detect internal flaws in materials. A transducer emits an ultrasonic beam that penetrates the material and reflects off discontinuities such as cracks or voids. The time taken for the waves to return is analyzed to determine the location and size of flaws.

This technique is widely used for evaluating metal structures, welds, and composites. Beyond flaw detection, it is effective for measuring material thickness, making it a key tool for predictive maintenance. In industries like oil and gas, ultrasonic testing monitors corrosion in pipelines and pressure vessels.

- Radiography

Radiography uses ionizing radiation, such as X-rays or gamma rays, to generate internal images of materials. The setup typically involves passing a radiation beam through the object to a photographic film or detector. Areas with discontinuities, like voids or cracks, appear darker on the image, allowing flaw identification.

This technique is highly valuable in manufacturing and construction for inspecting welds, castings, and metal structures. However, radiography requires strict safety precautions to protect operators and the environment from radiation exposure, including proper shielding and personal protective equipment.

- Magnetic Particle Testing

Magnetic particle testing is used on ferromagnetic materials and involves magnetizing the component and applying fine magnetic particles. These particles are attracted to areas with cracks or other discontinuities, forming visible patterns that indicate flaws.

This method is effective for detecting surface and near-surface flaws and is commonly used in manufacturing to inspect mechanical components like shafts, gears, and engine parts. Magnetic particle testing is relatively quick, cost-effective, and easy to perform, making it a popular choice across industries.

- Eddy Current Testing

Eddy current testing, or Foucault currents, generates electrical currents in conductive materials using an alternating magnetic field. These induced currents are influenced by the material’s geometry, composition, and discontinuities. Variations in the currents are analyzed to detect flaws such as cracks, corrosion, or wear.

This technique is primarily used on metallic materials and is suitable for complex components like tubes and coatings. Its ability to inspect hard-to-reach areas and perform high-speed measurements makes it valuable for equipment maintenance.

- Liquid Penetrant Testing

Liquid penetrant testing, also known as dye penetrant testing, involves applying a visible or fluorescent liquid to a component’s surface. After a set period, the liquid is removed, and a developer is applied to highlight discontinuities, making them visible.

This method is effective for detecting surface flaws in non-porous materials like metals, plastics, and ceramics. It is widely used to identify wear, cracks, and porosity, particularly in components unsuitable for other methods. The technique is simple and cost-effective but requires careful surface cleaning before testing.

- Thermography

Thermography uses infrared cameras to detect temperature variations on a surface. Discontinuities or flaws can affect heat transfer, resulting in distinct thermal patterns. This method is used to identify electrical overloads, air leaks in insulation systems, and degradation in composite materials.

Thermography is effective for evaluating electrical and mechanical systems and thermal insulation. Its ability to perform large-scale, real-time inspections without shutting down equipment saves time and resources.

- Visual Inspection

Visual inspection is the most basic yet essential NDT method. Though seemingly simple, it is a powerful tool for identifying visible issues like laminar anomalies, corrosion, or cracks. It can be performed with the naked eye or using tools like magnifiers, borescopes, or cameras.

Visual inspection is often the first step before applying other NDT methods, as it helps guide the selection of appropriate techniques. It is widely used across industries, from construction to automotive, for its speed and cost-effectiveness in ensuring safety and quality.

Final Considerations on NDT Techniques

NDT techniques offer a range of methods for evaluating and maintaining materials and structures across various industries. Each method’s suitability depends on the material, the type of flaw to be detected, and operating conditions.

Technological advancements continue to enhance NDT tools and techniques, making them more precise, efficient, and user-friendly. Qualified professionals are essential to ensure accurate inspections and reliable results.

By ensuring the safety, durability, and functionality of products and structures, NDT is a cornerstone of manufacturing and maintenance processes, preventing accidents and economic losses. Proper adoption of NDT techniques safeguards industrial operations.

Benefits of Non-Destructive Testing (NDT)

Non-Destructive Testing (NDT) plays a critical role in modern industry, enabling the evaluation of material and structural integrity without causing damage. Its importance extends beyond flaw detection, offering a range of benefits that impact safety, efficiency, and profitability. This section explores the key benefits of NDT and their significance for global industries.

- Preservation of Material Integrity

One of the most significant benefits of NDT is preserving material integrity. Unlike destructive testing, which damages the material to assess its properties, NDT allows components to be tested without compromising their functionality. This is crucial in industries like aerospace, civil construction, and automotive, where safety and performance are paramount.

NDT enables repeated inspections throughout a component’s lifespan, monitoring its condition and detecting changes, ensuring prolonged usability and reducing replacement costs.

- Early Flaw Detection

NDT is highly effective for early flaw detection. Regular testing can identify discontinuities like cracks or corrosion before they escalate into serious issues. This prevents catastrophic failures, legal liabilities, and reputational damage.

Early detection supports predictive maintenance, allowing companies to schedule repairs or replacements proactively, avoiding structural collapses or equipment failures.

- Cost Reduction

Implementing NDT can lead to significant cost savings. By identifying flaws early, NDT prevents costly repairs and unexpected downtime. This is especially relevant in industries with strict safety regulations, where failures can result in substantial financial losses.

Predictive maintenance based on NDT optimizes maintenance processes, focusing efforts on components that need attention and avoiding unnecessary expenses.

- Enhanced Safety

Safety is a critical aspect of NDT. In industries like oil and gas, construction, and transportation, NDT ensures components are free of hidden flaws that could lead to severe accidents, such as explosions or structural collapses. By monitoring material integrity, companies can take appropriate measures to protect workers and the public.

Effective NDT application results in safer, more reliable products, reinforcing a company’s reputation as a responsible provider.

- Time Efficiency

NDT offers significant time savings. Many techniques can be performed quickly and during active operations, minimizing downtime. This is crucial in industries where interruptions lead to financial losses.

Techniques like ultrasonic testing and thermography provide real-time data, enabling engineers to identify issues and make informed decisions swiftly, ensuring smooth operations.

- Improved Product Quality

NDT directly contributes to product quality. By ensuring materials are free of flaws and defects, companies can produce high-quality products that meet safety and performance standards. This is vital in industries with stringent quality requirements, such as medical equipment and aerospace manufacturing.

NDT also supports stricter quality control processes, boosting customer confidence and brand loyalty.

- Application Versatility

NDT is highly versatile, applicable to a wide range of materials and structures, from metals and plastics to composites and concrete. Techniques can be tailored to specific material needs, enabling inspections of diverse components regardless of shape, composition, or application.

For example, ultrasonic testing can assess steel structural beams, while thermography monitors operating electrical systems. This flexibility ensures suitable methods for any scenario.

- Sustainability Contribution

NDT supports sustainable industrial practices. By extending equipment and structure lifespan through continuous monitoring and predictive maintenance, NDT reduces waste from frequent replacements. This aligns with modern sustainability and environmental responsibility initiatives.

Early flaw detection also minimizes the need for large-scale emergency repairs, reducing resource and energy consumption in manufacturing and repair processes.

- Professional Training Opportunities

NDT implementation provides valuable opportunities for professional development. Training and certification in NDT are essential for ensuring accurate testing and fostering a culture of safety and quality within organizations. Skilled technicians and engineers are critical for effective method execution, ensuring detected flaws are addressed appropriately.

Ongoing training and updates on new techniques and technologies are vital to keep pace with evolving NDT practices.

Final Considerations on NDT Benefits

NDT offers a wide range of benefits that directly impact the safety, efficiency, and sustainability of industrial operations. From preserving material integrity to early flaw detection, NDT is a valuable strategy for companies aiming to optimize processes and ensure product quality.

By adopting NDT, companies protect assets, ensure worker safety, and enhance their market reputation and competitiveness. Investing in NDT technologies and qualified professionals is a critical step toward a safer, more sustainable future.

Applications of Non-Destructive Testing in Industry

Non-Destructive Testing (NDT) plays a vital role across various industrial sectors, ensuring the safety, reliability, and efficiency of products and structures. With a range of available techniques, NDT detects flaws and irregularities without causing permanent damage. This section explores NDT applications in different industries, highlighting their significance in each context.

- Aerospace Industry

The aerospace industry is one of the most critical areas for NDT due to the need for safety and reliability in aircraft and spacecraft components. Materials and structures exposed to extreme conditions require rigorous inspection to ensure no hidden flaws compromise integrity. Techniques like ultrasonic testing, radiography, and visual inspection are commonly used to evaluate welds, fuselages, and critical components.

NDT is not limited to new aircraft construction; it is also essential for maintenance and certification of operational aircraft. Regular inspections monitor the condition of key components like wings, engines, and control systems, preventing failures with potentially catastrophic consequences.

- Automotive Industry

In the automotive industry, quality and safety are paramount for consumer protection. NDT is used at various manufacturing stages, from inspecting raw materials to verifying component integrity during final assembly. Techniques like magnetic particle testing, ultrasonic testing, and eddy current testing detect flaws in metal structures, welds, and castings.

NDT also supports safety checks for vehicles in use, monitoring components like chassis, suspensions, and exhaust systems to ensure safe operation.

- Civil Construction

Civil construction greatly benefits from NDT. The structural integrity of buildings, bridges, tunnels, and other infrastructure requires regular inspections to ensure occupant and user safety. Techniques like ultrasonic testing, thermography, and visual inspection detect flaws in construction materials like concrete and steel.

NDT identifies issues such as cracks, corrosion, and degradation, enabling corrections before they become serious risks. It also ensures construction materials meet regulatory standards before use.

- Oil and Gas Industry

In the oil and gas sector, safety and reliability are critical. NDT monitors the integrity of pipelines, tanks, pressure vessels, and drilling platforms. Ultrasonic testing and radiography detect corrosion, cracks, and other flaws that could lead to leaks or accidents.

Predictive maintenance based on NDT is common in this industry, with regular inspections identifying issues before they escalate, preventing operational disruptions and ensuring personnel safety.

- Energy Industry

The energy industry, including electricity and nuclear power generation, uses NDT to ensure operational safety and efficiency. Techniques like ultrasonic testing and magnetic particle testing inspect turbines, generators, boilers, and other critical components operating under extreme conditions.

In nuclear energy, where safety is paramount, NDT verifies the integrity of structures and systems containing radioactive materials, preventing potential accidents through regular inspections.

- Metallurgical Industry

The metallurgical industry uses NDT to control material and manufacturing process quality. Ultrasonic testing, radiography, and eddy current testing inspect welds, castings, and forgings to ensure compliance with strict specifications. Detecting flaws during manufacturing minimizes waste and enhances final product quality.

NDT ensures finished products meet safety and quality standards required for applications in industries like automotive and aerospace.

- Food and Pharmaceutical Industry

In the food and pharmaceutical sectors, safety and quality are top priorities. NDT techniques like thermography and visual inspection verify the integrity of packaging, containers, and processing equipment, preventing contamination and ensuring compliance with safety and quality standards.

NDT also monitors filling and packaging processes, ensuring accuracy and efficiency. In pharmaceuticals, where precision is critical, NDT maintains high quality standards.

- Transportation Industry

The transportation industry, including railways, highways, and maritime transport, uses NDT to ensure the safety of vehicles, tracks, and ships. Ultrasonic and magnetic particle testing inspect railway tracks, while visual inspections and radiography verify the integrity of ship structures and oil platforms.

NDT is essential for public safety, preventing accidents and ensuring transportation systems remain in optimal condition. Proactive NDT inspections address issues before they cause disruptions or risks.

- Plastics and Composites Industry

Composites and plastics are used in diverse applications, particularly in civil construction and aerospace engineering. NDT verifies the integrity of these structures, detecting flaws like delaminations, porosity, and adhesion failures. Ultrasonic testing and thermography assess composite product quality, ensuring performance and safety standards are met.

NDT’s ability to inspect composites is vital for high-performance applications like aircraft fuselages and racecar components, where early flaw detection prevents catastrophic failures.

Final Considerations

NDT is fundamental across nearly all industrial sectors, ensuring the integrity, safety, and quality of products and structures. With a variety of adaptable techniques, NDT meets diverse material and application needs, making it a preferred choice for monitoring critical components.

As industries evolve and demand greater safety and efficiency, NDT’s importance will continue to grow. Investing in NDT technologies and qualified professionals strengthens companies’ market positions while protecting their most valuable assets: products and employees.

In summary, NDT plays an essential role in various industries, significantly contributing to product and structural safety, quality, and efficiency. This article explored key NDT techniques, their benefits, and applications in sectors like aerospace, automotive, civil construction, oil and gas, and more. Early flaw detection, material integrity preservation, and damage-free inspections are just some of the many advantages of NDT. As industries advance and seek more effective safety and quality solutions, NDT’s importance will continue to rise. Thus, investing in NDT technologies and trained professionals is increasingly critical to ensure integrity and reliability in an ever-changing industrial landscape.