Metallographic analysis of metals is a critical technique for understanding material characteristics and quality. This article explores the methods and techniques used, as well as the importance of this process in industry. Understanding how to perform and interpret this analysis is vital for applications in various engineering and manufacturing fields. Keep reading to discover everything about this essential topic!

1. What is Metallographic Analysis of Metals?

Metallographic analysis involves a set of techniques used to investigate the microstructure of metallic materials. This analysis is crucial for understanding the mechanical, chemical, and physical properties of metals, as well as providing insights into their manufacturing and heat treatment processes.

When discussing metallographic analysis, we refer to a detailed examination that reveals vital information about the internal structure of metals, such as phase distribution, grain size, and the presence of impurities. These insights are fundamental for industrial applications where material quality and reliability are paramount.

Importance of Metallographic Analysis

Metallographic analysis plays a vital role in industries such as construction, automotive, aerospace, and electronics. It is used to:

- Verify material quality: Ensures materials meet the required quality standards for specific applications, critical in sectors like construction and manufacturing of critical components.

- Diagnose failures: Helps identify the causes of component failures, such as wear, fractures, or corrosion, enabling corrective measures.

- Optimize manufacturing processes: Evaluates how manufacturing and heat treatment processes affect the internal structure, leading to improvements in production efficiency and quality.

Techniques of Metallographic Analysis

Common techniques used in metallographic analysis include:

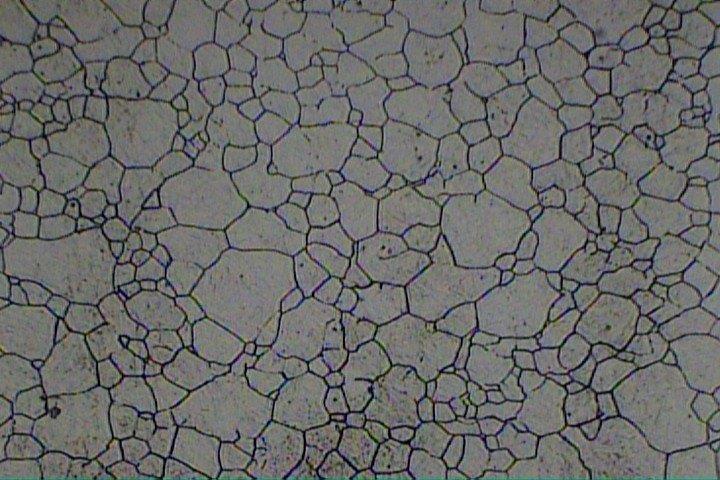

- Optical Microscopy: Uses visible light to examine metal samples. Samples are carefully prepared, polished, and sometimes etched to highlight specific features. It allows visualization of small structures like grains and inclusions.

- Scanning Electron Microscopy (SEM): Offers higher resolution than optical microscopy, enabling observation at the nanoscale. It uses an electron beam to generate images and can provide chemical composition data through Energy-Dispersive X-ray Spectroscopy (EDS).

- X-ray Diffraction (XRD): Determines the crystalline structure of metals, revealing phase information and often used in conjunction with other techniques for a comprehensive microstructural analysis.

Sample Preparation for Metallographic Analysis

Sample preparation is a critical step, as errors can lead to distorted or misleading results. The process typically involves:

- Cutting: Samples are carefully cut to avoid damaging the internal structure, using high-precision cutting tools.

- Mounting: Samples may be embedded in resin to facilitate handling and maintain shape during subsequent steps.

- Polishing: The sample surface is polished using progressively finer abrasives to remove scratches and imperfections.

- Etching: Chemical solutions are applied to reveal the microstructure, highlighting different phases for analysis.

Interpretation of Results

Interpreting metallographic analysis results requires deep knowledge of the techniques and materials science. Key elements observed include:

- Grain Size: Influences mechanical properties. Smaller grains typically enhance strength, while larger grains may indicate brittleness.

- Phases Present: Different phases have unique properties, and their identification and proportion are critical for assessing material quality.

- Inclusions and Imperfections: Non-metallic inclusions or defects can compromise material performance. Analysis quantifies and qualifies these to evaluate their impact.

Practical Applications of Metallographic Analysis

Metallographic analysis has numerous practical applications. In the automotive industry, it ensures components like axles and gears meet strength and durability requirements. In civil engineering, it evaluates the structural integrity of metal beams and columns to ensure safety.

In research and development, metallographic analysis is essential for testing new alloys and developing lighter, stronger materials, particularly in aerospace, where weight reduction without compromising strength is critical.

Challenges and Future of Metallographic Analysis

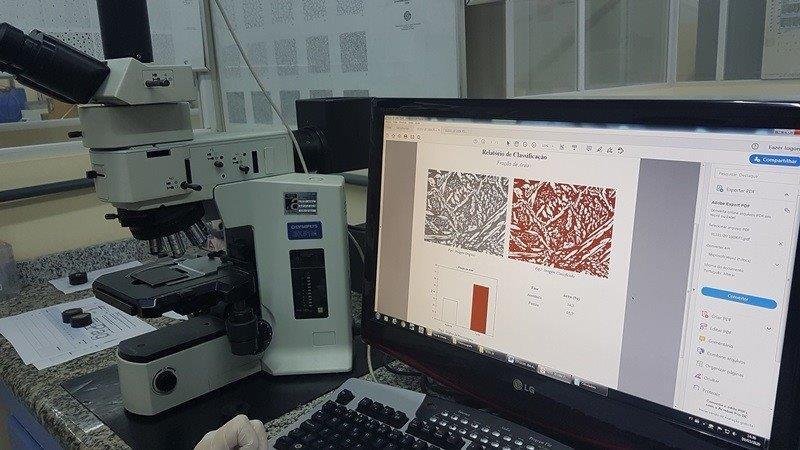

Despite its power, metallographic analysis faces challenges, such as the complexity of microstructures and the need for increasingly sophisticated analytical methods. In the future, integrating advanced technologies like artificial intelligence and machine learning is expected to enhance the accuracy and efficiency of analysis, aiding in interpreting large datasets and improving material property predictions.

Metallographic analysis will continue to solidify its role as an essential tool for both industry and research, driving innovation and ensuring the quality and safety of metallic products across various applications.

2. Techniques Used in Metallographic Analysis

Metallographic analysis is a broad field critical for understanding the material properties of metals and alloys. Various techniques are employed to visualize and characterize microstructures accurately. This section explores the main techniques, detailing their applications, advantages, and limitations.

Sample Preparation

Proper sample preparation is crucial, as inadequate preparation can compromise results. The process involves:

- Cutting: Samples are cut to avoid excessive heating, which could alter properties. Techniques like abrasive saws or precision cutting are used.

- Mounting: Small or fragile samples are mounted in resin to ease handling and analysis.

- Polishing: Abrasives of decreasing grit size are used to smooth the sample surface, ensuring clear visibility of internal structures.

- Etching: Chemical solutions reveal the microstructure by highlighting different phases.

Optical Microscopy

Optical microscopy is a traditional, widely used technique that employs visible light and optical lenses to visualize metal microstructures.

Types include:

- Bright-Field Microscopy: Directly observes illuminated samples, useful for viewing phase boundaries and interactions but may lack contrast for some features.

- Dark-Field and Phase-Contrast Microscopy: Enhance contrast, making them effective for observing fine details like grain boundaries and inclusions.

Scanning Electron Microscopy (SEM)

SEM uses an electron beam to produce high-resolution images of sample surfaces, offering:

- High Resolution: Enables nanoscale observation of microstructural details.

- Chemical Composition Analysis: Combined with EDS, SEM identifies elemental composition and quantities.

- Three-Dimensional Imaging: Provides near-3D visualization of metal surfaces, aiding comprehensive material analysis.

X-ray Diffraction (XRD)

XRD determines the crystalline structure of metals by analyzing X-ray diffraction patterns, useful for:

- Phase Identification: Identifies phases related to mechanical and thermal properties.

- Residual Stress Analysis: Evaluates stresses affecting material integrity over time.

- Texture Analysis: Determines crystalline texture, optimizing manufacturing processes.

Micro-Computed Tomography (Micro-CT)

Micro-CT is a non-destructive technique providing 3D visualizations of internal microstructures using X-rays. Benefits include:

- Non-Destructive Internal Viewing: Allows visualization without damaging the sample.

- Phase Quantification: Quantifies porosity and internal defects critical for quality assessment.

- Grain Geometry Analysis: Provides data on grain distribution and geometry, informing mechanical behavior.

X-ray Photoelectron Spectroscopy (XPS)

XPS determines the chemical composition and electronic state of metal surfaces, offering:

- Contaminant Analysis: Detects surface contaminants affecting material properties.

- Chemical Reaction Studies: Investigates surface reactions, particularly in corrosion and oxidation research.

- Surface Treatment Validation: Verifies the effectiveness of treatments like anodizing or electroplating.

Fourier Transform Infrared Spectroscopy (FTIR)

FTIR is used complementarily to characterize polymeric or composite materials alongside metals, providing:

- Coating Evaluation: Assesses protective coating properties on metal surfaces.

- Organic Contaminant Identification: Detects contaminants impacting performance, especially in corrosive environments.

3. Importance of Metallographic Analysis in Industry

Metallographic analysis is crucial across industries, influencing product quality, safety, and manufacturing efficiency. It enables detailed investigation of metal microstructures, empowering engineers to make informed decisions about material selection and treatment. This section discusses its importance in sectors like civil construction, automotive, aerospace, and metallurgy.

Quality and Reliability of Materials

Metallographic analysis ensures material quality by:

- Verifying Standards Compliance: Confirms materials meet industry standards, critical for safety and performance.

- Identifying Manufacturing Defects: Detects inclusions or porosity to prevent failures.

- Ensuring Structural Integrity: Prevents risks in critical applications by validating material properties.

Role in the Automotive Industry

In the automotive sector, metallographic analysis is vital for:

- Material Performance Evaluation: Assesses wear and corrosion resistance for components like axles and gears.

- Alloy Development: Validates new alloys for lightweight, high-performance applications.

- Critical Component Certification: Ensures safety-critical parts meet specifications.

Impact in the Aerospace Industry

The aerospace industry demands high material performance and safety, where metallographic analysis:

- Ensures Strict Quality Control: Validates engine and structural components for passenger safety.

- Supports New Material Development: Tests alloys like titanium under extreme conditions.

- Prevents Failures: Identifies microstructural variations to avoid catastrophic incidents.

Relevance in Civil Construction

In civil construction, metallographic analysis ensures:

- Structural Steel Quality: Verifies steel properties for beams and columns.

- Corrosion Monitoring: Develops strategies to prevent material degradation.

- Safety Assurance: Ensures compliance with safety codes to minimize structural failure risks.

Enhancing Manufacturing Processes

Metallographic analysis optimizes manufacturing by:

- Adjusting Processing Parameters: Evaluates heat treatment effects to improve outcomes.

- Implementing Quality Control: Reduces waste and enhances productivity.

- Diagnosing Issues: Identifies and corrects manufacturing defects.

Research and Development of New Materials

In R&D, metallographic analysis supports:

- Product Innovation: Develops lighter, stronger materials.

- Prototype Testing: Validates new alloys and composites.

- Material Compatibility: Assesses interactions in composite applications.

4. Interpretation of Metallographic Analysis Results

Interpreting metallographic analysis results is essential for understanding material properties and behavior. This section examines the steps involved, focusing on how data is extracted and applied to enhance material quality and safety.

Sample Preparation and Examination

The quality of sample preparation directly impacts result accuracy. Polishing, etching, and handling must be meticulous. Samples are examined using techniques like optical microscopy, SEM, and XRD, each providing unique insights.

Grain and Phase Identification

Key focuses include:

- Grain Size: Smaller grains enhance strength (Hall-Petch relationship). Size is measured using image analysis or statistical methods.

- Phases Present: Identifying and quantifying phases (via XRD or microscopy) determines material performance.

Observations of Imperfections and Defects

Analysis identifies:

- Non-Metallic Inclusions: Compromise strength and ductility.

- Porosity: Indicates manufacturing issues affecting performance.

- Fractures and Wear: Reveals failure causes through fracture pattern analysis.

Fracture Mechanism Interpretation

Fracture analysis distinguishes:

- Ductile Fracture: Shows significant deformation, with features like dimples.

- Brittle Fracture: Exhibits smooth, rapid failure surfaces under excessive load.

Relating Structure to Properties

Analysis correlates microstructure with properties like hardness or wear resistance, guiding material selection and treatment for specific applications.

Practical Applications of Interpretation

- New Material Development: Optimizes alloy performance.

- Predictive Maintenance: Identifies wear patterns to reduce costs and risks.

- Component Certification: Ensures compliance with quality standards.

Challenges in Interpretation

Challenges include complex microstructures, contradictory results, and the need for skilled analysts. Deep material science knowledge is essential.

Connection to Technological Advances

AI and machine learning are transforming interpretation by automating analysis, identifying patterns, and predicting properties, enhancing efficiency and accuracy.

Conclusion

Metallographic analysis is not just a laboratory technique but a cornerstone of quality and durability in various industries. This article explored the methods, techniques, and their significance in ensuring material integrity and reliability.

The interpretation of results provides deep insights into metal microstructures, enabling process optimization, failure diagnosis, and new material development. With advancing technologies and growing demand for innovative solutions, metallographic analysis will play an increasingly vital role in engineering and manufacturing, ensuring excellence in material quality and safety in critical applications.

Mastering this technique is essential for professionals seeking excellence in material quality and product innovation.