Optical emission spectrometry is a critical analytical technique for determining the composition of materials. In this article, you will discover how this methodology works, its unique advantages, and its wide-ranging applications in industries and sciences. Keep reading to better understand these comparisons with other analytical techniques and their essential contributions.

How Optical Emission Spectrometry Works

Optical emission spectrometry is an analytical technique used to identify and quantify the elements present in a sample. This methodology relies on the excitation of atoms by an energy source, such as an electrical discharge or arc. When the excited atoms return to their ground state, they emit radiation at specific wavelengths characteristic of each element.

Initially, the sample is prepared and introduced into the excitation unit, where the energy provides conditions for the atoms and ions to enter high-energy states. The excitation process causes electrons in the atoms to move to higher energy levels. This state is unstable, resulting in the release of energy in the form of light when the electrons return to their normal states. The emitted light can then be broken down into a spectrum that reflects the elemental composition of the sample.

The spectrometer, a crucial component of the system, captures the emitted light and splits it into its component wavelengths using a prism or diffraction grating. The detector then measures the light intensity at each wavelength, allowing the identification of which elements are present. The light intensity at a specific wavelength is proportional to the concentration of the corresponding element in the sample.

One of the major advantages of optical emission spectrometry is its ability to analyze multiple elements simultaneously in a short period. This is made possible by its sensitive detectors and advanced software, which can quickly process and interpret the acquired data. This aspect is particularly important in the analysis of industrial materials where efficiency and speed are essential.

The precision of spectrometry is unparalleled, offering highly reproducible results. This can be crucial in scientific and industrial applications where accuracy is vital. Understanding how this technology works is essential for improving quality control processes and developing new materials.

Another significant point is that this technique covers a wide range of concentrations, from trace levels to higher concentrations, making it extremely versatile for various applications. This means that even small variations in composition can be detected and measured, which is vital for many applications requiring strict control of trace components.

The continuous development of technologies in the areas of excitation sources and detectors has enhanced the capabilities of optical emission spectrometry. Improvements in excitation sources have brought greater stability and sensitivity to the process, while advances in detectors ensure more accurate and faster measurements.

In an industrial context, optical emission spectrometry is widely used for quality control and verification of the composition of metal alloys and other materials. The ability to quickly measure material composition in environments like foundries significantly improves the efficiency and accuracy of production processes.

Furthermore, its application extends to fields such as geology, environmental analysis, and even archaeology, demonstrating its versatility. In these fields, it can help reveal the composition of volcanic lava, quantify elements in soils and rocks, or analyze artifacts and archaeological remains to determine their origin or period.

Finally, optical emission spectrometry is an essential technique when integrated into general analysis procedures. In a testing laboratory, it is traditionally used in conjunction with other analyses, such as atomic absorption spectrometry or X-ray fluorescence analysis, to provide a comprehensive and accurate understanding of material composition.

With its precision, speed, and multi-element capability, optical emission spectrometry remains an indispensable tool in various fields, from industry to scientific research. Understanding its functionalities provides valuable insight that can be applied to improve analytical processes and outcomes across multiple sectors.

Advantages in Materials Analysis

Optical emission spectrometry offers several significant advantages in materials analysis, making it a preferred choice in many industrial and scientific sectors. Its ability to perform simultaneous multi-element analyses is one of its greatest attractions. Instead of analyzing individual elements separately, this technique allows the detection and quantification of multiple elements at once, increasing efficiency and reducing analysis time.

Precision and accuracy are critical aspects of any material analysis. Optical emission spectrometry provides high precision, ensuring that measurements are repeatable and results are consistent across different samples and over time. This is particularly valuable in industrial applications, such as quality control of metal products, where small variations in composition can significantly impact the quality of the final product.

Another benefit is its versatility in measuring a wide range of concentrations, from trace to high levels. This makes it suitable for various applications requiring rigorous monitoring of minor components that are critical to determining the final properties of materials. This versatility allows for easy adaptation to different analysis contexts.

Optical emission spectrometry is also valued for its speed. In industrial environments, where time is often a critical factor, the ability to generate results quickly can help identify composition issues immediately, avoiding material and time waste. This agility in obtaining results supports real-time decision-making during manufacturing processes.

The implementation of this technique does not require chemical reagents, unlike some traditional analytical techniques, making it a more environmentally friendly and cost-effective alternative. Additionally, the absence of reagents eliminates risks associated with handling potentially hazardous substances, promoting a safer working environment.

Instrumental flexibility is another significant advantage. Optical emission spectrometry instruments are available in various configurations and can be adapted with different accessories to enhance analysis according to the specific needs of each application.

Beyond its application in metals and metal alloys, this technique can also be used to analyze other materials such as glass, ceramics, and plastics, expanding its scope of use. This makes it a valuable tool for scientists and engineers working on the development of new materials who need comprehensive and accurate characterization.

Ease of use and automation are additional benefits. Modern optical emission spectrometers are often equipped with user-friendly interfaces and powerful software that guide users through the analysis process, making it accessible even to operators with less experience. Process automation reduces human interference, increasing accuracy and minimizing operational errors.

Lastly, this technique plays an important role in quality and sustainability by allowing manufacturers to precisely control raw materials and final products, contributing to resource efficiency and waste reduction. Thus, its adoption goes beyond simple material analysis and aligns with greener and more sustainable manufacturing practices.

Industrial and Scientific Applications

Optical emission spectrometry is a powerful and widely used tool in both industrial and scientific contexts due to its ability to provide precise and rapid elemental analysis across various matrices. Its industrial applications are extensive, spanning from the manufacturing of metals and alloys to the petrochemical industry and the production of glass and ceramics. One of its primary uses is in the quality control of metal alloys, where ensuring the correct proportion of components is essential to achieve the desired properties in the final product.

In metallurgy, this technique enables the analysis of alloy components during melting or refining processes, ensuring that the chemical composition meets specifications before the products are formed or treated. This prevents the production of non-compliant batches, saving time and resources.

In the chemical industry, optical emission spectrometry is employed to control the purity of refined products. This is critical in applications where composition directly affects performance and safety, such as in the automotive and aerospace industries. The technique’s precision in identifying trace impurities ensures that products meet stringent quality standards.

In the field of polymers, this technique also has its place, enabling the analysis of elements present in additives used to modify the properties of plastic materials. Careful analysis and assurance of the correct additive concentration are crucial for the future performance of plastics in their respective end-use applications.

In scientific research, optical emission spectrometry plays a vital role in the study and development of new materials. Researchers use this technique to investigate and understand the properties of different substances. This is particularly relevant in materials science and chemistry, where a detailed understanding of composition is essential for exploring new applications and improving existing materials.

In the environmental sector, this technique is used to monitor pollutants in soils, water, and the atmosphere. By analyzing contaminating elements, it is possible to identify the sources of pollutants and develop strategies for mitigation, monitoring, and environmental remediation, making it an important tool for sustainable and environmentally protective policies.

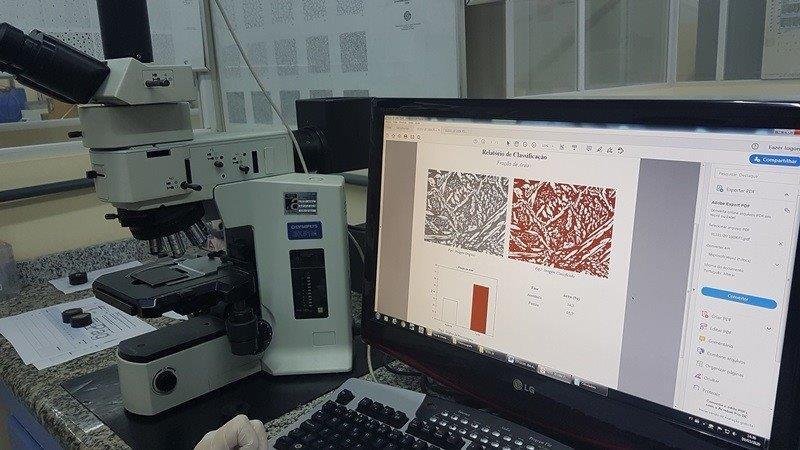

Academic and industrial laboratories frequently equip themselves with optical emission spectrometers to integrate routine analyses into their research workflows. In a testing laboratory, spectrometry is part of a suite of techniques available to provide a comprehensive view of material composition, helping to correlate this with mechanical behavior or other properties.

Additionally, in the fields of geology and archaeology, this technique aids in determining the composition of rocks, soils, and cultural artifacts. Analyzing these materials allows conclusions to be drawn about the geological formation of a region or provides insights into the conditions and technologies of ancient civilizations.

Optical emission spectrometry is also relevant in clinical trials and research, where it can be used to analyze biological and pharmaceutical samples. The precise and rapid identification of trace elements and contaminants in medications can be vital to ensuring their efficacy and safety.

With its diverse applications and ability to provide accurate and rapid analyses, optical emission spectrometry continues to prove its value across a wide range of industrial and scientific applications. It offers valuable insights that support not only manufacturing and scientific research but also the sustainable exploration of our resources and the understanding of our natural environment.

Comparison with Other Analytical Techniques

Optical emission spectrometry is a versatile and widely used technique, but other analytical methodologies are often compared in terms of precision, analysis speed, and applicability. Each technique has its unique characteristics and may be more or less suitable depending on the desired analysis context.

One commonly compared technique is atomic absorption spectrometry (AAS). While optical emission spectrometry allows for simultaneous multi-element analysis, AAS typically analyzes one element at a time, which can be a limitation in terms of time efficiency. However, AAS is highly precise for specific trace elements and is ideal for very low concentrations, where its sensitivity excels.

X-ray fluorescence (XRF) is another comparable technique used to analyze a wide range of elements. XRF is highly non-destructive, making it ideal for applications in archaeology and art, where sample preservation is critical. Although XRF offers multi-element analysis, its accuracy can be influenced by the sample matrix, and in some cases, optical emission spectrometry may provide more precise results in industrial environments requiring high accuracy.

In contrast, chromatography, coupled with more specific techniques such as mass spectrometry, offers a high level of detail in analyzing complex compounds, making it particularly valuable in biological sciences and organic chemistry. However, optical emission spectrometry excels in the direct quantitative analysis of metals and elements in samples, where these other techniques may require more complex preparation.

Chemical assay analysis, though somewhat outdated, is occasionally used due to its simplicity and low operational cost. However, optical emission spectrometry provides a more modern alternative, delivering faster results with less susceptibility to issues associated with chemical reagent handling, such as hazardous waste and incomplete reactions.

Other techniques, such as nuclear magnetic resonance (NMR), are better suited for characterizing molecular structures and interactions of organic compounds. However, NMR is less effective for the rapid and precise analysis of elemental composition in solid materials, where optical emission spectrometry maintains an advantage.

A clear advantage of optical emission spectrometry is its adaptability and ease of automation within industrial processes. This makes it a valuable component in a testing laboratory, enabling a continuous flow of samples with minimal intervention, which is ideal for environments where time and productivity are critical.

Nevertheless, the choice of analytical technique should consider factors such as the specificity of the elements to be analyzed, the sample form, and the concentration range. In many cases, complementary techniques are combined to provide a comprehensive and detailed analysis, maximizing accuracy and efficiency.

Thus, optical emission spectrometry, with its numerous advantages, remains a fundamental tool in various industries and scientific research, particularly when rapid and precise multi-element analysis is required. At the same time, it integrates well into broader solutions that use other techniques to complement analytical data.

After exploring the various aspects of optical emission spectrometry, its critical role in materials analysis is evident. From its efficient and precise operation to its numerous advantages in metal analysis, this technique stands out across various industrial and scientific sectors. Its applications range from quality control in production lines to environmentally critical research, proving its indispensability and versatility. Moreover, compared to other analytical techniques, optical emission spectrometry positions itself as a fast and highly adaptable tool, complementing and often surpassing other methodologies in terms of efficiency and analytical depth.

Whether in the precise determination of elemental composition or in supporting robust industrial processes, the importance of optical emission spectrometry is undeniable. We invite you to explore more about this technique through other content that covers its specific applications and case studies to expand your knowledge and fully leverage its potential in your field. Share your experiences or questions and join this ongoing conversation about this fascinating and innovative topic.

How do you plan to use optical emission spectrometry in your own projects or studies? Reflect on this and start applying these ideas to make a difference in your results!