Industrial Painting

Painting and Coating Quality Control

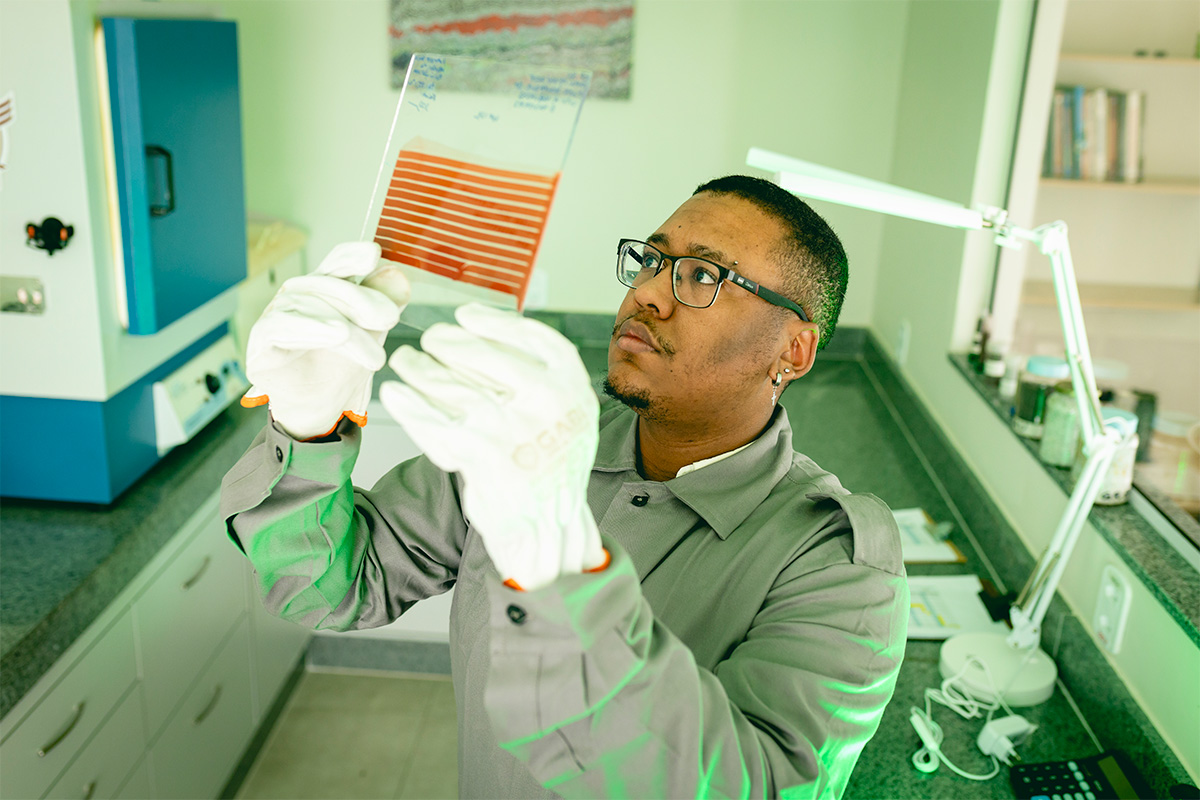

Priner operates a specialized analysis laboratory dedicated to testing equipment, methods, and coatings for anticorrosive protection, assessing essential parameters to ensure the quality of the products and services delivered to our clients.

A pioneer in Brazil, our laboratory is led by an N3 Coating Inspector and staffed by inspectors qualified in accordance with ABNT NBR 15218, ISO 9001, ISO 14001, and OHSAS 18001 standards.

Below is a list of tests and inspections performed in our laboratory:

- Oven cure acceleration testing;

- Preparation of test panels and application of coating systems for qualification, in compliance with client-specified standards;

- Particle size distribution (granulometry) test;

- Coating thickness measurement test;

- Surface roughness test;

- Sag resistance test (Anti-Sag Test);

- Hiding power (coverage) test;

- Pull-off adhesion test;

- Dust contamination test;

- NORSOK M-501 qualification test;

- Bresle test.

We also perform additional tests and inspections through partner laboratories:

- Consistency (UK method);

- Sag resistance, µm;

- Bend test on conical mandrel, % elongation;

- Density (specific gravity), g/cm³;

- Flash point, °C;

- UVA radiation resistance;

- Abrasion resistance, mg / 1,000 cycles;

- Heating followed by cooling test;

- Salt spray resistance, h;

- Impact resistance, J;

- Fineness of grind, µm;

- Atlas cell test;

- Autoclave test;

- Pressure drying time;

- Touch dry time;

- Recoat drying time;

- Pot life (mixed material working life);

- Cyclic corrosion test;

- Cathodic disbondment;

- Immersion resistance;

- Gloss – GU;

- Water analyses (hardness, pH, iron, silica, and chloride).

Galery

Contact us and request a quote