.Metallographic analysis of metals is a fundamental technique for understanding the structure and properties of metallic materials. Mastering this analysis is crucial for ensuring the quality and durability of final products. In this article, we outline the six essential steps for conducting effective metallographic analysis and achieving reliable results.

What is Metallographic Analysis?

Metallographic analysis encompasses a set of techniques used to study the internal structure of metals and their alloys. This involves preparing samples through cutting, polishing, and often chemical etching to reveal microscopic details.

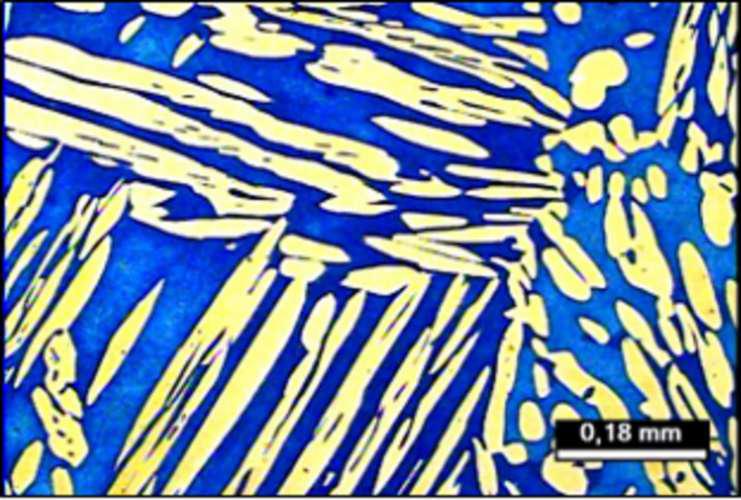

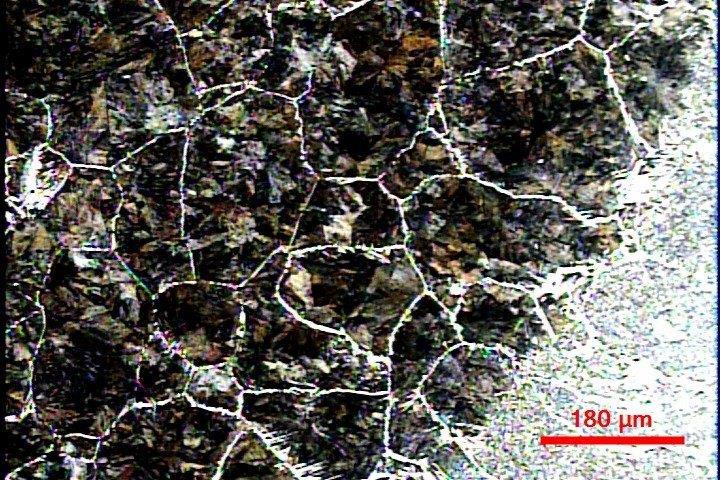

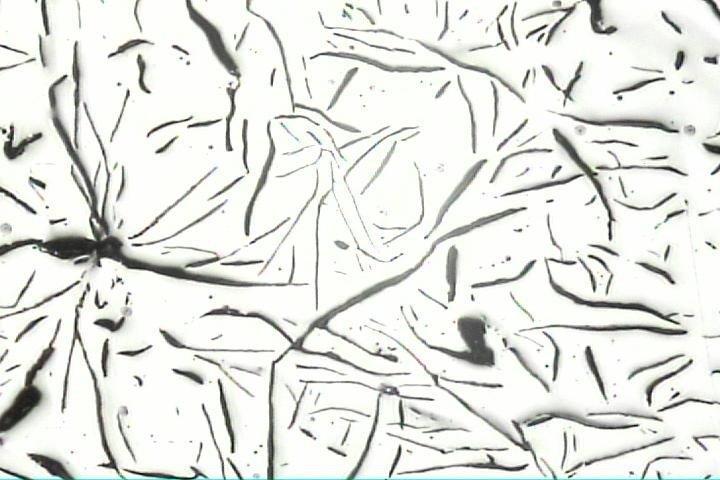

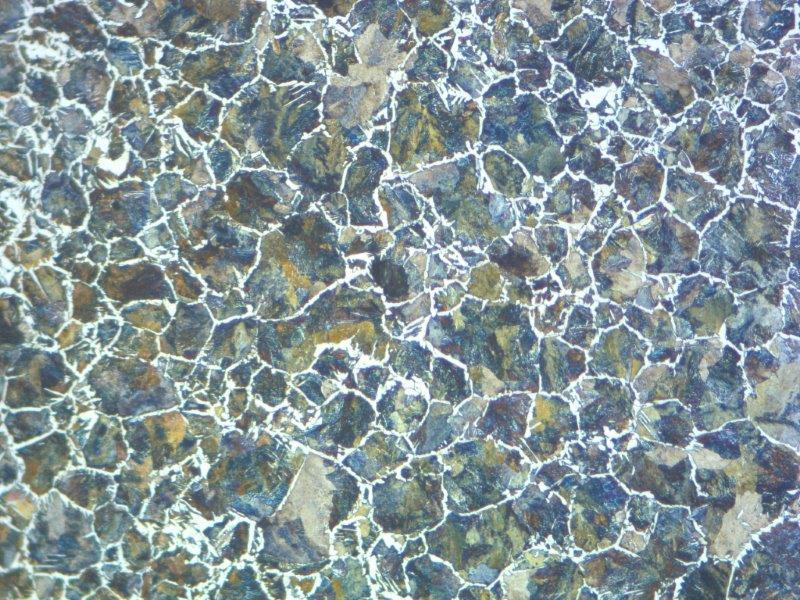

The primary goal is to identify the material’s microstructure, including grain distribution, phases present, and potential defects. These factors directly influence mechanical properties such as strength, hardness, and ductility. Common techniques include optical microscopy and electron microscopy, which enable visualization of the microstructure at various magnifications.

In essence, metallographic analysis is a vital tool in materials science, ensuring metals meet the quality and performance standards required by industry.

Importance of Metallographic Analysis

The significance of metallographic analysis cannot be overstated, particularly in industries requiring materials with specific properties and high reliability. It is essential for ensuring metals used in critical applications—such as aerospace, automotive, and construction—meet quality and performance standards.

Key benefits include:

- Detection of Internal Flaws: Identifies inclusions, porosity, or discontinuities invisible to the naked eye, preventing structural failures.

- Process Optimization: Provides insights into how manufacturing and heat treatment affect microstructure, enabling adjustments for desired properties.

- Research and Development: Supports the development of innovative alloys by analyzing microstructures to meet specific application needs.

By identifying issues early, metallographic analysis prevents catastrophic failures, reduces rework costs, and enhances product durability, making it indispensable for quality assurance and innovation.

Equipment Required for Metallographic Analysis

Effective metallographic analysis requires specialized equipment to ensure precision and quality. The key tools include:

- Sample Cutting Machine: Cuts metal into manageable samples with precision to avoid damaging the microstructure.

- Polishing Equipment: Automatic polishers smooth the sample surface for clear microscopic observation.

- Chemical Reagents: Etching solutions reveal the microstructure by highlighting phases and features.

- Optical Microscope: Enables observation of the microstructure at various magnifications, identifying grains, phases, and defects.

- Scanning Electron Microscope (SEM): Provides high-resolution surface imaging and chemical composition analysis.

- Image Analysis Software: Quantifies microstructural features like grain size and phase percentages.

These tools ensure comprehensive and accurate analysis, contributing to the quality and safety of industrial products.

6 Essential Steps in Metallographic Analysis

Below are the six critical steps for conducting a successful metallographic analysis, ensuring reliable and actionable results:

- Sample Selection

Choose a representative sample from the material to ensure results reflect the bulk properties. Consider the material’s application and potential defect areas.

- Sample Cutting

Use a precision cutting machine to section the sample, minimizing heat and mechanical damage that could alter the microstructure.

- Mounting

Embed small or fragile samples in resin to facilitate handling and maintain structural integrity during polishing and analysis.

- Grinding and Polishing

Grind the sample with progressively finer abrasives, followed by polishing to achieve a mirror-like surface, essential for clear microstructural visualization.

- Etching

Apply chemical etchants to reveal the microstructure, highlighting grain boundaries, phases, and defects for microscopic examination.

- Microscopic Examination and Analysis

Use optical or electron microscopy to observe the microstructure. Analyze images with software to quantify grain size, phase distribution, and defects, correlating findings with material properties.

Common Techniques in Metallographic Analysis

Several techniques are widely used to examine metal microstructures, each with specific applications:

- Optical Microscopy: Uses visible light to assess grain shape, size, and phase distribution. Ideal for initial evaluations.

- Scanning Electron Microscopy (SEM): Offers high-resolution surface imaging and chemical analysis, ideal for detailed studies.

- X-ray Diffraction (XRD): Identifies crystalline phases and structures, crucial for understanding mechanical properties.

- Microhardness Testing: Measures resistance to plastic deformation at a microscopic level, assessing phase hardness.

- Cold Metallography: Prepares samples without heat to preserve sensitive microstructures.

- Fractography: Analyzes fracture surfaces to identify failure causes, critical for diagnosing manufacturing or operational issues.

These techniques, when combined, provide a comprehensive understanding of metal microstructures, enabling informed material decisions.

Interpretation of Results

Interpreting metallographic analysis results is critical for understanding material properties and performance. Key aspects include:

- Microstructure Evaluation: Identify grain size, shape, phase distribution, and defects, which influence mechanical properties like strength and ductility.

- Standards Comparison: Compare results to industry standards to ensure compliance with quality and performance requirements.

- Defect Analysis: Assess cracks, porosity, or inclusions to identify manufacturing issues like contamination or improper cooling.

- Mechanical Property Correlation: Relate microstructure to properties like hardness or tensile strength to predict performance.

- Documentation and Reporting: Document methods, observations, and conclusions in detailed reports for future reference and process improvement.

Interpretation requires technical expertise to translate microstructural data into actionable insights for material quality and application.

Applications of Metallographic Analysis in Industry

Metallographic analysis is critical across various industries:

- Automotive Industry: Ensures components like axles and gears meet strength and durability standards, enhancing vehicle safety.

- Aerospace Industry: Validates alloys for aircraft and spacecraft, ensuring performance under extreme conditions.

- Construction Industry: Assesses steel and aluminum quality for structural integrity in buildings and bridges.

- Energy Industry: Evaluates turbine and generator components for durability in harsh operating environments.

- Heavy Equipment Industry: Ensures gears and shafts withstand high loads and wear.

- Research and Development: Supports the creation of innovative alloys for advanced applications.

These applications highlight metallographic analysis as a cornerstone for quality, safety, and innovation in material use.

Conclusion

Metallographic analysis is an essential tool for ensuring the quality and safety of metallic materials across industries. By providing deep insights into microstructures, it enables informed decisions on material use and treatment.

From detecting defects to optimizing manufacturing processes, this technique significantly impacts product performance and durability. As demand for high-quality materials grows, metallographic analysis will remain vital. Investing in this practice ensures compliance with industry standards, enhances competitiveness, and drives innovation, contributing to safer and more efficient industrial applications.