Initial Challenge

Welding a 3,750 m³ tank with 172 vertical joints on the shell and 95 joints on the bottom is a highly complex task. It requires strict quality control, execution precision and compliance with technical standards to ensure the tank’s structural integrity and leak-tightness.

Proposed Solution

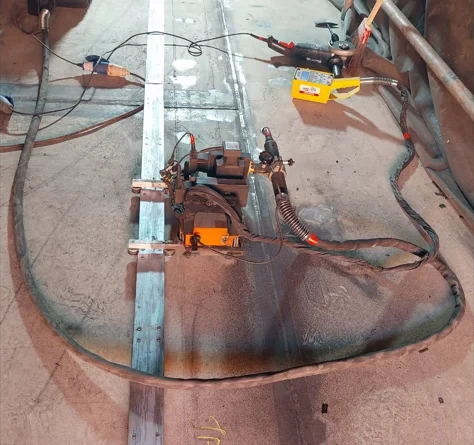

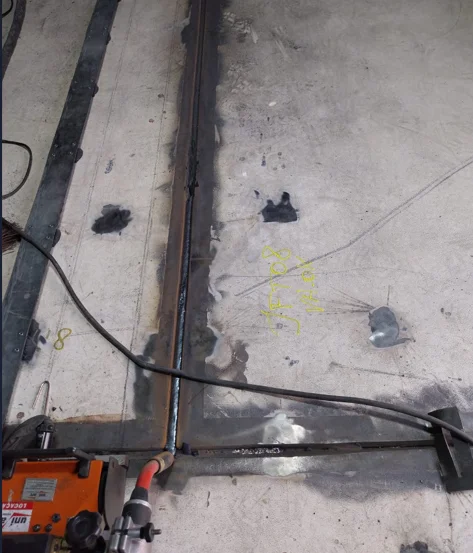

To improve the process, we implemented an automated welding robot for both vertical and horizontal welds. Controlled by a joystick and guided by a master rail, the robot brought several benefits to the project:

- Increased productivity: automation enabled a steady welding pace, reducing overall project time;

- Improved weld quality: the robot ensured more uniform weld beads, reducing variability and rework — with defect rates of just 0.16% on shell welds and 0.07% on bottom welds;

- Fewer defects: stable, controlled welding parameters significantly decreased the occurrence of flaws;

- Reduced welder fatigue: remote operation via joystick lowered physical effort and exposure to heat and spatter, improving ergonomics;

- Higher safety: less movement at height and reduced contact with the electric arc made the work environment safer;

- Full compliance with standards: robotic precision ensured all welds met technical requirements, guaranteeing long-term leak-tightness and structural performance.

The implementation of automated welding proved to be a major step forward in efficiency and quality for large-scale industrial tank construction projects.