Introduction

In the industrial sector, equipment safety and reliability are essential for the efficient operation of critical systems. This case study presents the evaluation of a valve made from ASTM A694 low-alloy steel with an internal Inconel weld overlay, in which discontinuities were identified that could compromise performance and operational safety. The analysis included both non-destructive and destructive testing to determine the origin and extent of the issue.

Objective

To assess the structural integrity of the valve and identify the nature of the discontinuities using advanced testing techniques, ensuring the safety and efficiency of the component.

Methodology

The following tests were conducted:

- Non-Destructive Testing: Phased array ultrasonic testing and ToFD to detect internal discontinuities;

- Chemical Testing: Optical emission spectrometry to verify material composition;

- Mechanical Testing: Hardness, tensile, and impact tests to evaluate mechanical properties;

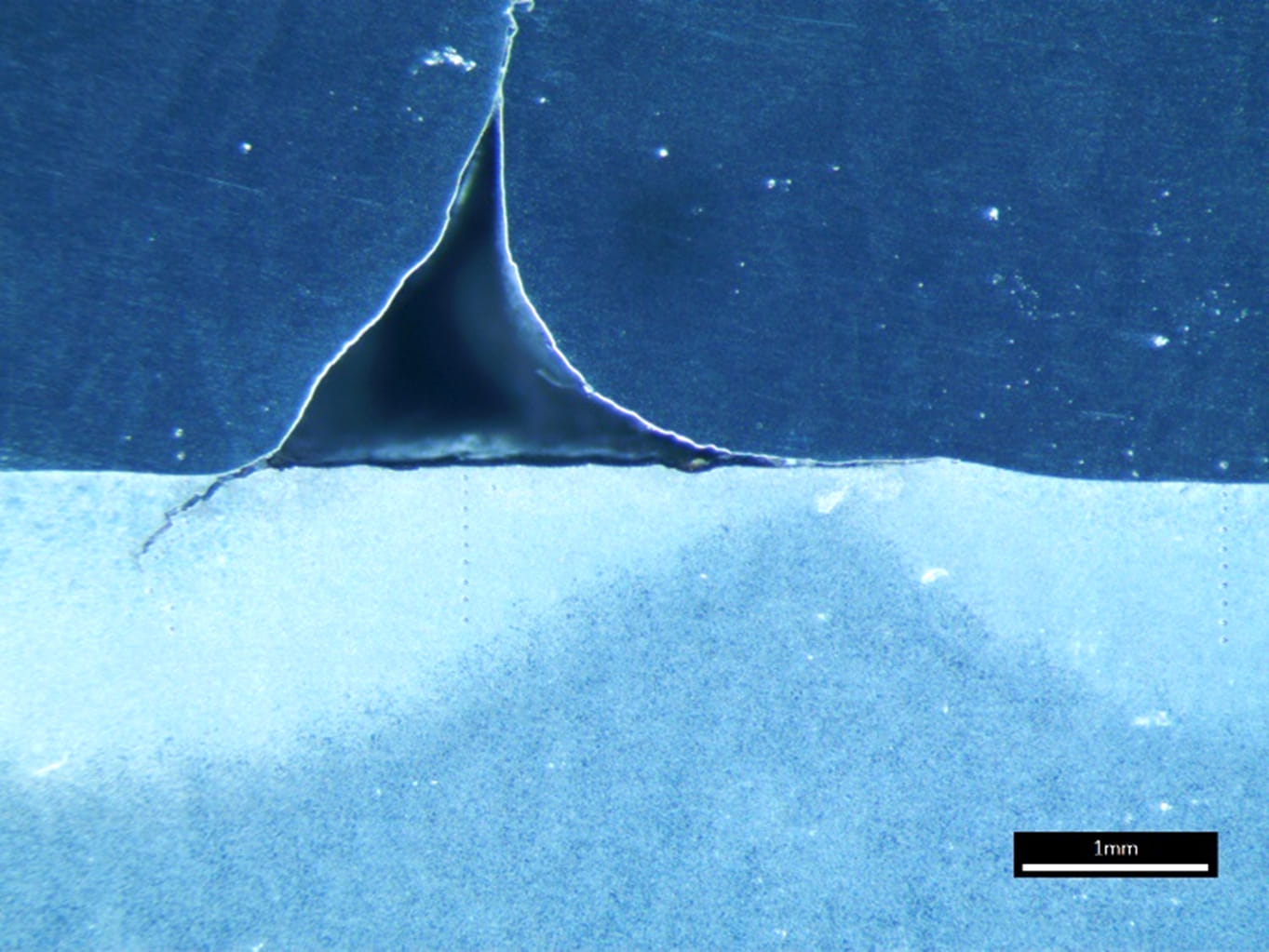

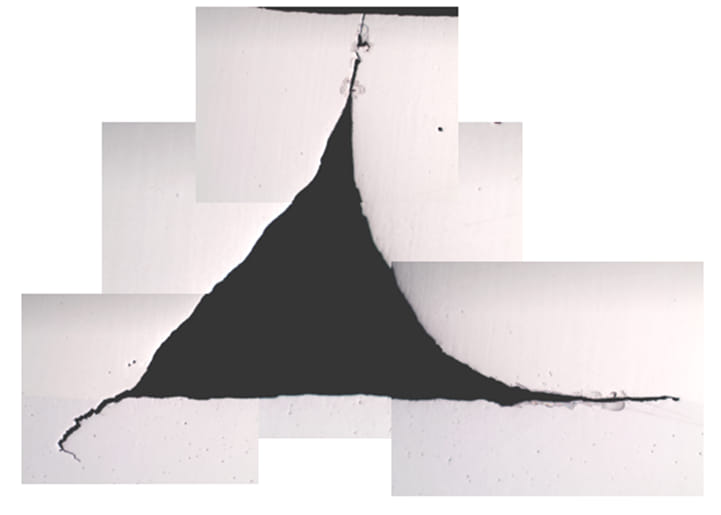

- Metallographic Analysis: Macro- and micrographic examination to identify discontinuity morphology;

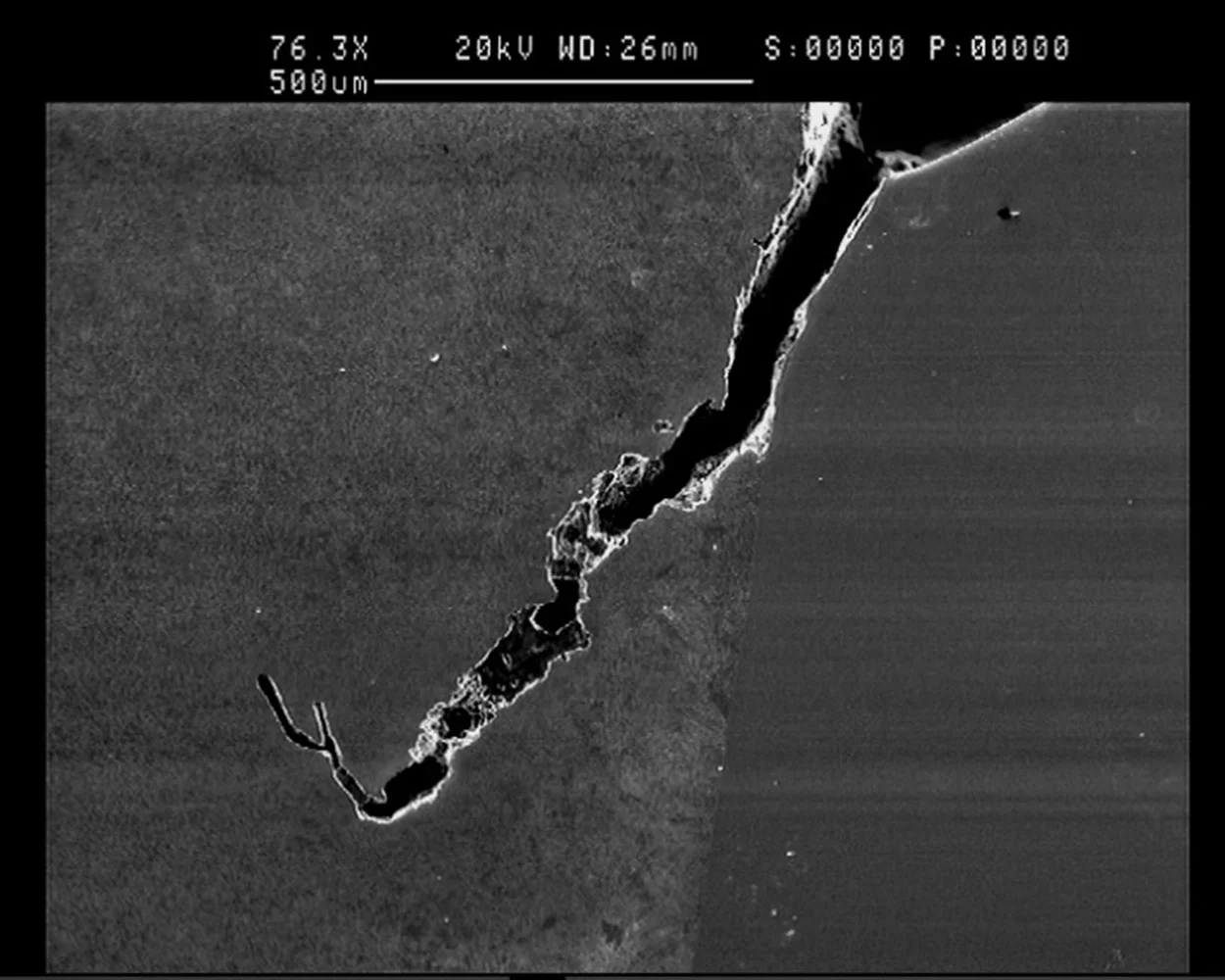

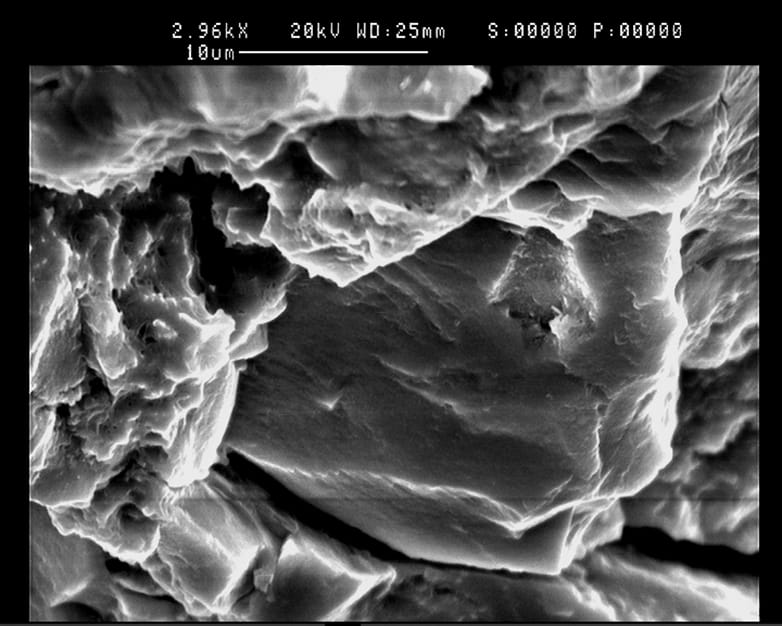

- Scanning Electron Microscopy (SEM): Detailed characterization of failure mechanisms and crack progression.

Results

The analysis revealed discontinuities at the interface between the base metal and the weld overlay, characterized by intergranular cracking originating from lack of fusion and weld porosity. Mechanical test results showed that impact resistance and hardness were within acceptable limits, except near the cracking region, where a significant microstructural variation was observed.

Conclusion and Recommendation

The investigation enabled a detailed understanding of the discontinuity and indicated that the cracking likely resulted from welding conditions, including welding parameters, surface preparation and temperature control. It is recommended to review welding procedures and implement stricter quality control measures to prevent recurrence. The outcome of this analysis supported informed decision-making to maintain the operational integrity of the equipment.