Integrity and Inspection Engineering ensures the safety, reliability and performance of industrial structures and equipment. We continuously monitor operating conditions to ensure compliance with national and international standards. Why is it important? - Reduces operational risks and prevents unplanned downtime - Detects damage before it becomes critical - Extends asset lifespan through preventive maintenance Structural inspections identify wear, corrosion and cracks that can affect the performance of structures. At Priner, we rely on certified professionals, specialized solutions and training programs to ensure the safety and efficiency of industrial assets.

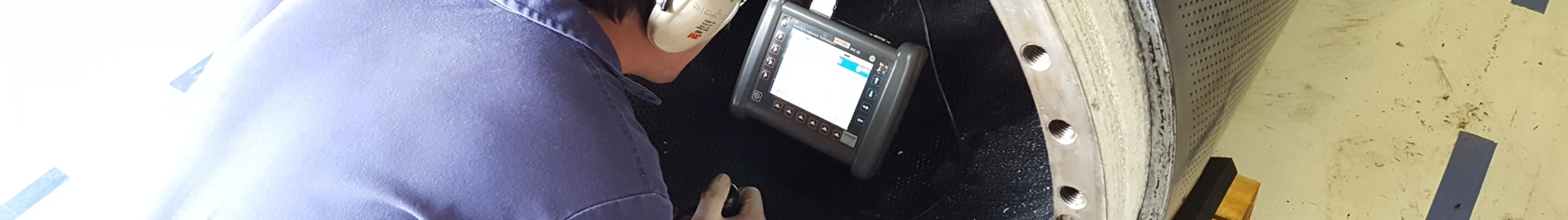

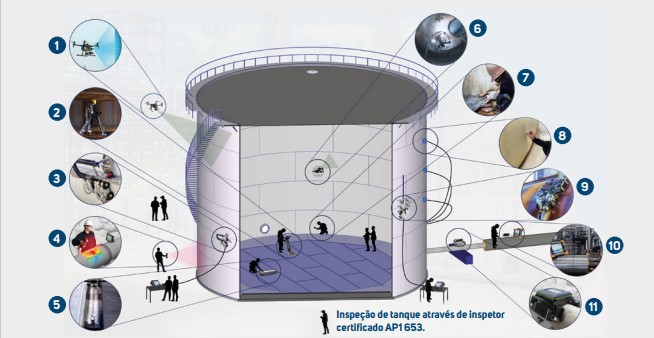

Inspection of materials and equipment without compromising their integrity, ensuring the safety and reliability of industrial assets. - Automated Phased Array Ultrasonic Testing (PAUT) - Conventional Ultrasonic Testing - Welding Inspection - Thickness Measurement - Magnetic Particle Testing (MT) - Liquid Penetrant Testing (PT) - Hardness Testing - Visual Testing (VT)

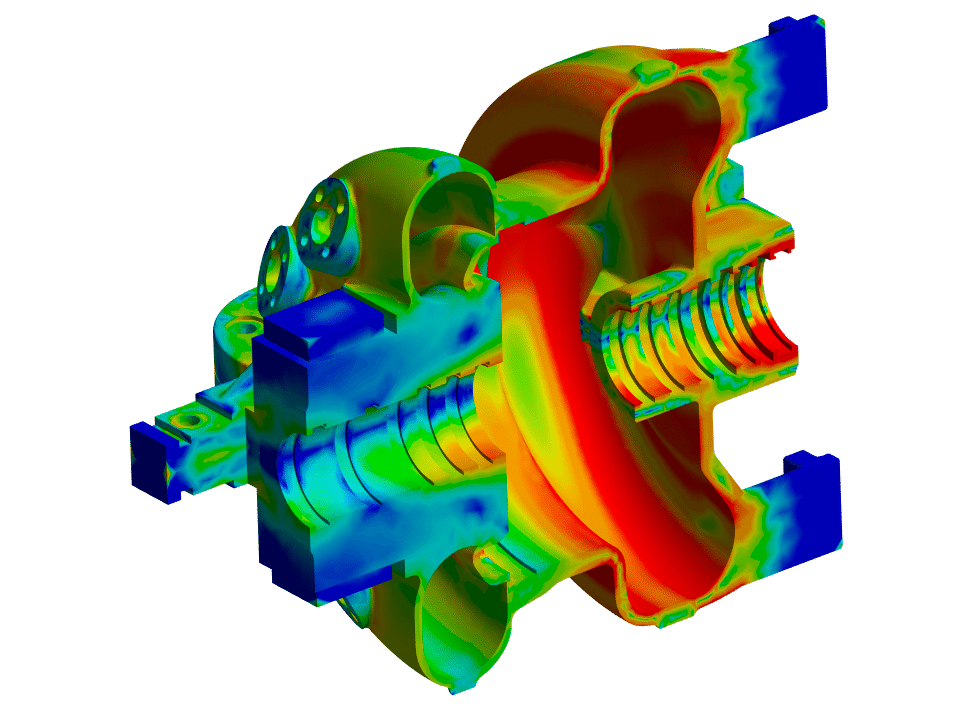

Solutions for assessing and monitoring the structural integrity of assets, ensuring compliance with the most rigorous technical standards.

From developing and qualifying welding procedures to conducting weld inspections (destructive or non-destructive), including welder training and qualification.

Innovative solutions integrating technology, technical expertise and advanced methodologies to optimize processes and increase operational reliability.

Material testing and failure analysis to identify defects, wear and non-conformities that may affect equipment and system performance. Learn more

Training programs in Integrity and Inspection Engineering, as well as consulting services and R&D project development.

Inspection software and integrated platforms developed by Priner to boost productivity and enhance inspection program control.

- External Remote Visual Inspection - Corrosion Mapping by MFL (Magnetic Flux Leakage) - Ultrasonic Corrosion Mapping | C-Scan - 3D Laser Scanning - Vacuum Box Leak Testing - Internal Remote Visual Inspection - Conventional NDT - Acoustic Emission Testing - Weld Inspection using Phased Array and ToFD - Pulsed Eddy Current Testing (PEC) - Short-Range Guided Wave Testing

The execution of all work starts and ends with Access, and we are specialists in this area.

Laboratory testing ensures the quality and safety of materials in sectors such as sugar and ethanol, metal-mechanic, food and beverage, pulp and paper, oil and gas, equipment manufacturing, and more.

Priner has extensive experience in Geotechnics, consistently combining modern solutions, high technical capability, and solid expertise in executing a wide range of services. One of the main technologies used by our company is the execution of injected piles, also known as pressurized anchoring.

The pressurized habitat is the ideal solution in terms of cost and operation at sites with strict safety requirements, such as offshore oil production rigs, refineries and petrochemical plants and terminals.

Our teams composed of qualified professionals and equipped with cutting-edge technology to deliver the best solutions in conventional and advanced inspection techniques for equipment assessment.

Internal inspection of water, sewage, and other effluent networks carried out using robotic technology to assess the actual condition of the installations, as well as maintenance, cleaning, and descaling needs.

Efficient solutions for conventional and portable thermal insulation systems, firewalls and acoustic systems, offering maximum productivity and quality.

A qualified technical team develops tailor-made solutions in all market segments, taking into account the reduction of environmental risks and increase the projected life of the plants.

We offer a broad portfolio of Integrity and Advanced Engineering Solutions for Industrial Equipment in the United States, ensuring the safety and reliability of your assets.

Technique used to restore, reinforce, or replace underground infrastructure networks, such as water, sewage, gas, and drainage systems, without the need for extensive excavations.

Priner operates in the infrastructure sector with a focus on solving its clients’ structural issues while minimizing the impact on their operations.