Priner specializes in laboratory testing, ensuring the quality and safety of materials. Our tests contribute to the reliability and performance of projects in sectors such as: sugar and ethanol, metal-mechanic, food and beverage, pulp and paper, oil and gas, equipment manufacturing, among others. - Mechanical Testing - Chemical Analysis - Metallography - Failure Analysis We rely on a highly qualified team, equipment calibrated with RBC traceability, and ISO 17025 certification, ensuring compliance with the most rigorous market standards and requirements. REQUEST A QUOTE

Mechanical testing determines material properties such as strength, ductility, and toughness, ensuring predictability and safety. These tests assess material behavior under different conditions, helping prevent failures and extend the service life of components. - Dynamic tests: fracture toughness, axial fatigue, crack growth rate - Tensile test - Charpy impact test - Hardness tests: Brinell, Rockwell, Vickers, Barcol - Bend test - Specific/customized tests REQUEST A QUOTE

Chemical analyses are essential not only for verifying material composition but also for identifying contaminants, corrosion, and scaling, ensuring proper quality and performance. - Optical Emission Spectrometry (S-OES) - Combustion analysis and X-ray fluorescence (XRF) - Energy Dispersive X-ray Spectroscopy (EDS) REQUEST A QUOTE

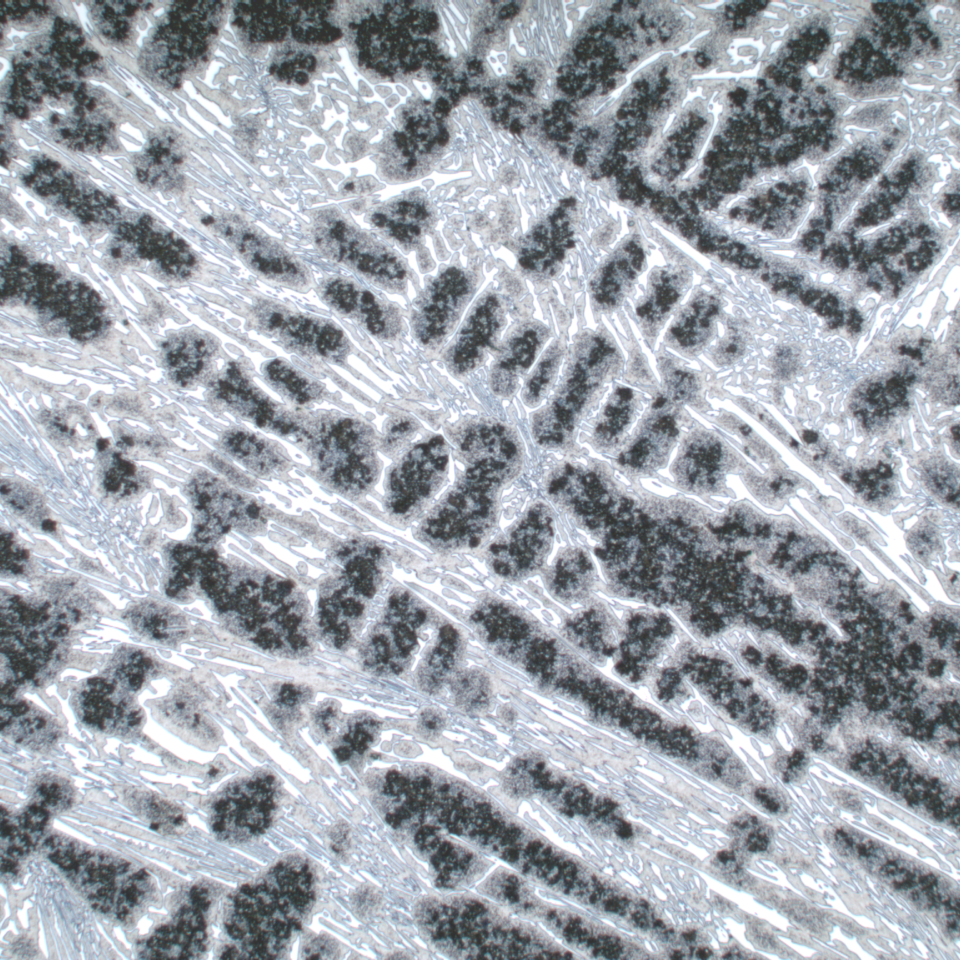

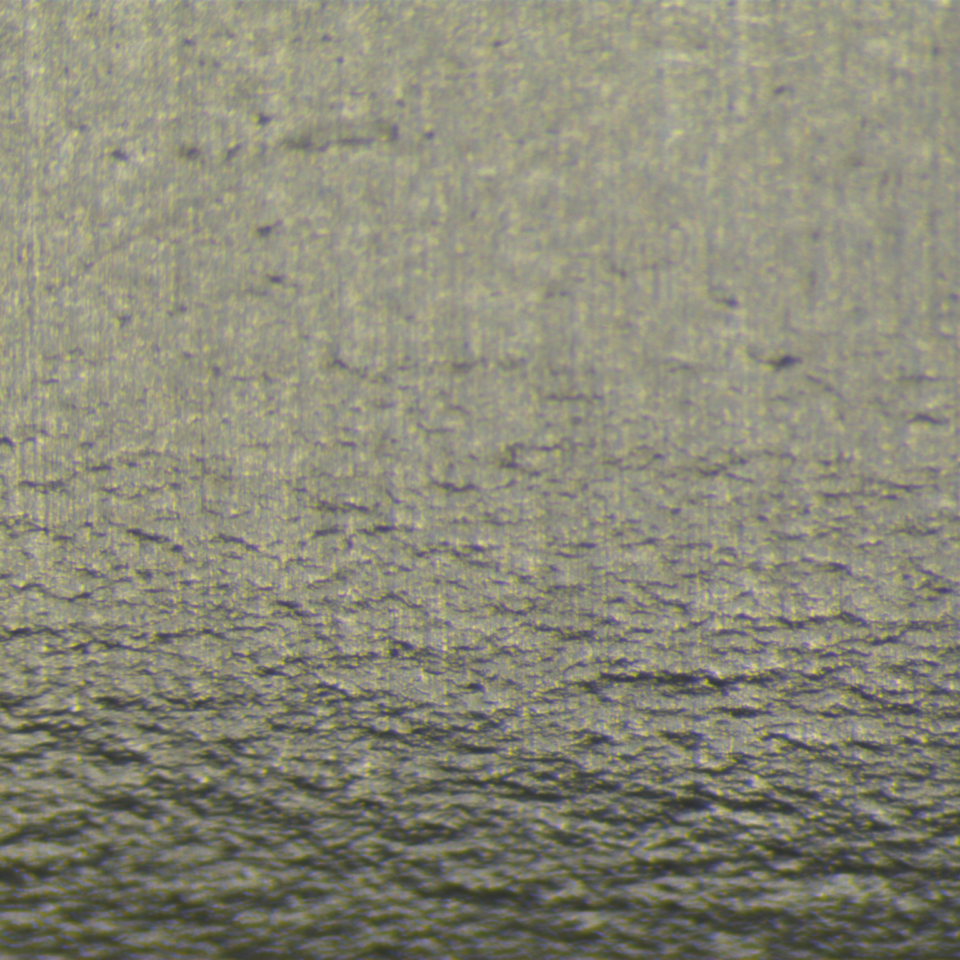

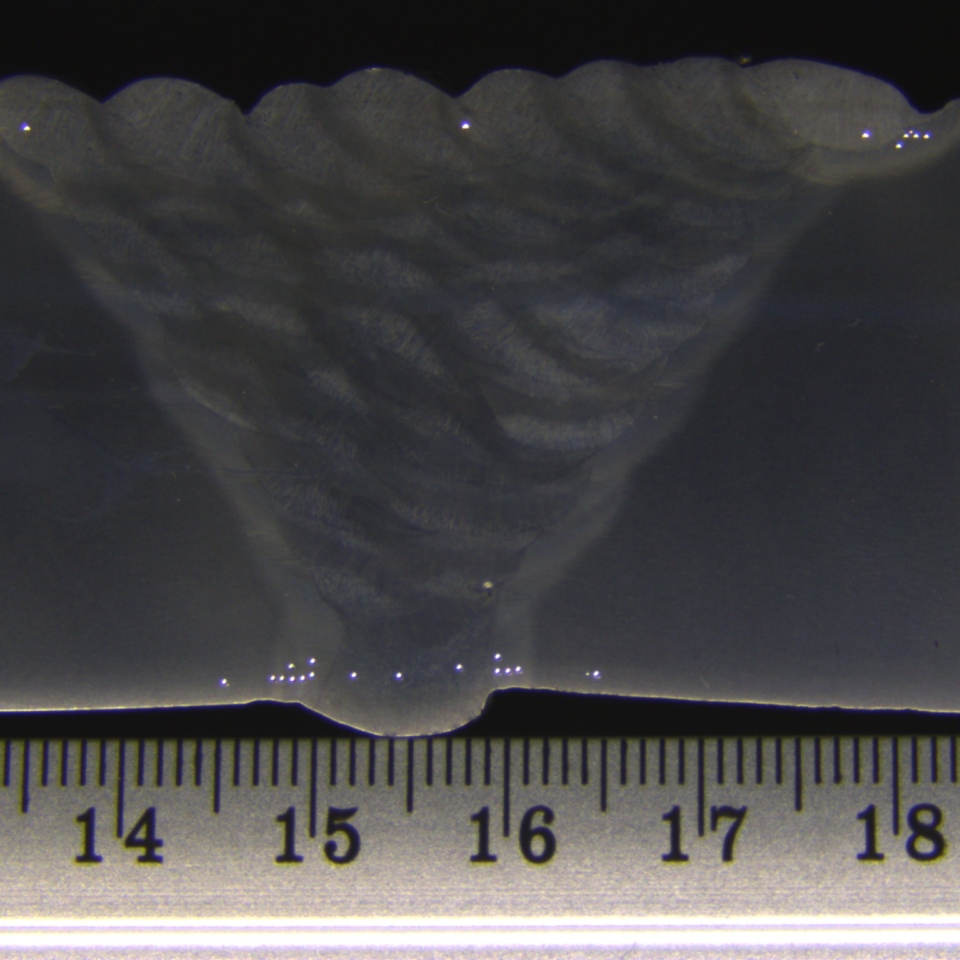

Metallographic analysis evaluates the structure of metals, identifying manufacturing processes, heat treatments, and impurities. This technique supports quality control, inspections, and ensures material reliability. - Micrography: grain size, inclusions, graphite classification, microstructure - Macrography: welds, segregations, thread profile, and discontinuities REQUEST A QUOTE

Corrosion testing is essential to assess material resistance in aggressive environments, ensuring durability and performance. These tests help predict failures, optimize material selection, and reduce operational costs. - Susceptibility to intergranular corrosion - Pitting corrosion - Weld decay - Testing in salt spray and humidity chambers REQUEST A QUOTE

Using advanced technology and fast diagnostics, we deliver precise solutions without removing components, minimizing downtime and optimizing operations. - Metallographic replication - Hardness testing - Positive Material Identification (PMI) REQUEST A QUOTE

Procedure and Welder Qualification We ensure welding safety and quality with complete services for procedure qualification (PQR/WPS) and welder qualification (WPQ), ensuring compliance with national and international standards. This minimizes the risk of failures and guarantees greater reliability in critical processes. - Laboratory testing - Welding documentation - On-site monitoring REQUEST A QUOTE

Failure analysis identifies the root causes of issues in components and equipment, preventing recurrences and optimizing operational reliability. Using advanced techniques, it helps minimize costs, reduce downtime, and enhance industrial safety. REQUEST A QUOTE

The execution of all work starts and ends with Access, and we are specialists in this area.

Laboratory testing ensures the quality and safety of materials in sectors such as sugar and ethanol, metal-mechanic, food and beverage, pulp and paper, oil and gas, equipment manufacturing, and more.

Priner has extensive experience in Geotechnics, consistently combining modern solutions, high technical capability, and solid expertise in executing a wide range of services. One of the main technologies used by our company is the execution of injected piles, also known as pressurized anchoring.

The pressurized habitat is the ideal solution in terms of cost and operation at sites with strict safety requirements, such as offshore oil production rigs, refineries and petrochemical plants and terminals.

The Integrity Engineering and Inspection team at Grupo Priner is composed of qualified professionals and equipped with cutting-edge technology to deliver the best solutions in conventional and advanced inspection techniques for equipment assessment.

Internal inspection of water, sewage, and other effluent networks carried out using robotic technology to assess the actual condition of the installations, as well as maintenance, cleaning, and descaling needs.

Efficient solutions for conventional and portable thermal insulation systems, firewalls and acoustic systems, offering maximum productivity and quality.

A qualified technical team develops tailor-made solutions in all market segments, taking into account the reduction of environmental risks and increase the projected life of the plants.

We offer a broad portfolio of Integrity and Advanced Engineering Solutions for Industrial Equipment in the United States, ensuring the safety and reliability of your assets.

Technique used to restore, reinforce, or replace underground infrastructure networks, such as water, sewage, gas, and drainage systems, without the need for extensive excavations.

Priner operates in the infrastructure sector with a focus on solving its clients’ structural issues while minimizing the impact on their operations.